Plastic single/multi-cavity PP PC HDPE injection handle mold

栏目:MOULD BLOG 发布时间:2024-11-09

As the market demand for plastic handles continues to increase, plastic handle mold have become an indispensable tool in the manufacturing industry.

The handle mold is specially designed for the manufacture of handles made of durable and easy to process plastic materials, such as PP, HDPE and other plastics. These handles can be made in a variety of shapes, sizes and colors, giving their products a unique and striking look that is used by companies all over the world to produce high-quality fast-moving goods.

1.For the supermarket shopping basket handle mold, this handle inner is empty, so that we will make air-assisted hand mold.

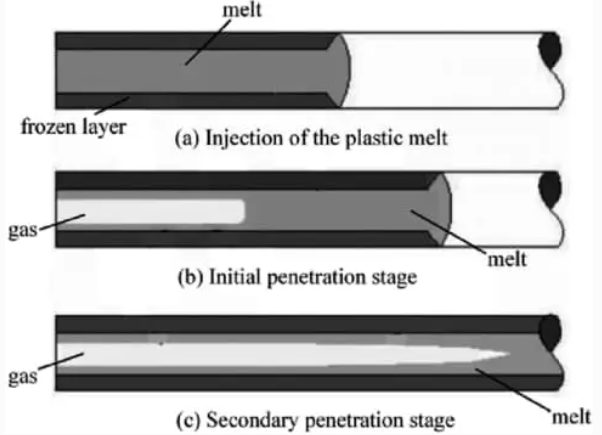

The gas-assisted injection molding process is divided into three stages(like below picture)

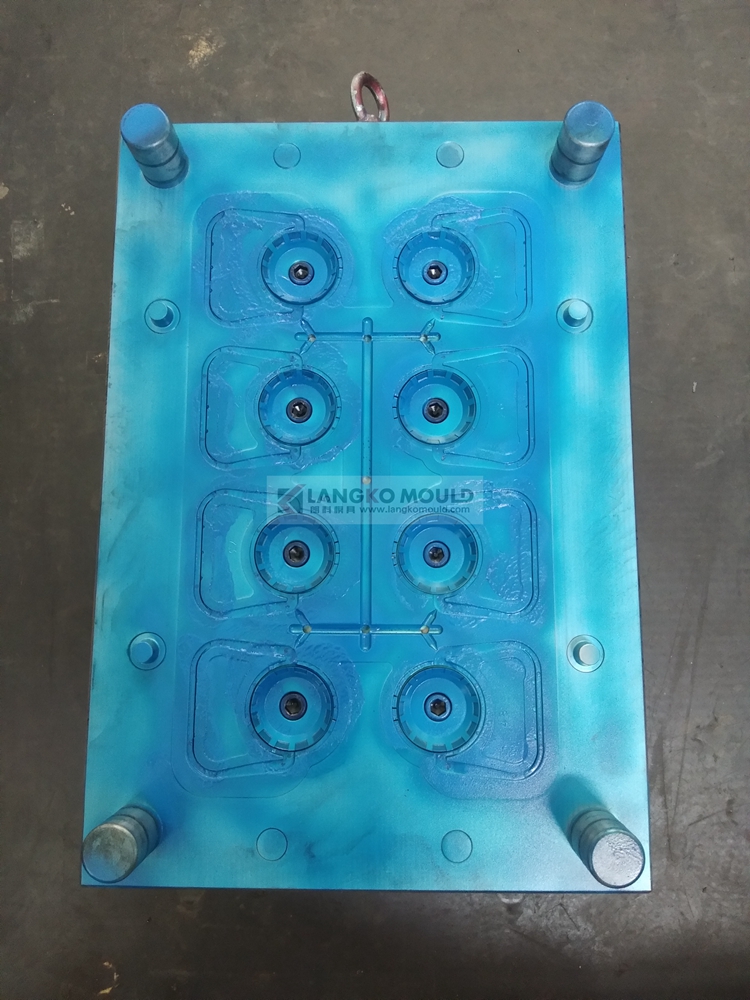

2. For the normal water bottle handle mold and drawing handle mold etc, this kind of handle are could make multi cavity, like 4/8/12/16/20...cavities. And this mold is a normal two plate mold, will demold by injection pins.

For the handle mold cooling line, the good cooling system could make the cooling time shorter, so that it is have high requirement for the mold design. The cooling line could make close to the mold surface, and evenly distributed to ensure effective heat transfer, thus providing uniform cooling.

The handle mold temperature also affects the cycle time, and the mold temperature range will be adjusted accordingly according to the different plastic materials. The higher the mold temperature, the better the surface quality, but the longer the cycle time.

Langko Mould Co., could supply the good cooling design, good quality handle mold to you, if you have any interests, please feel free to contact us.

Wechat/whatsapp: +86-18158636422

86-0576-81122860

86-0576-81122860