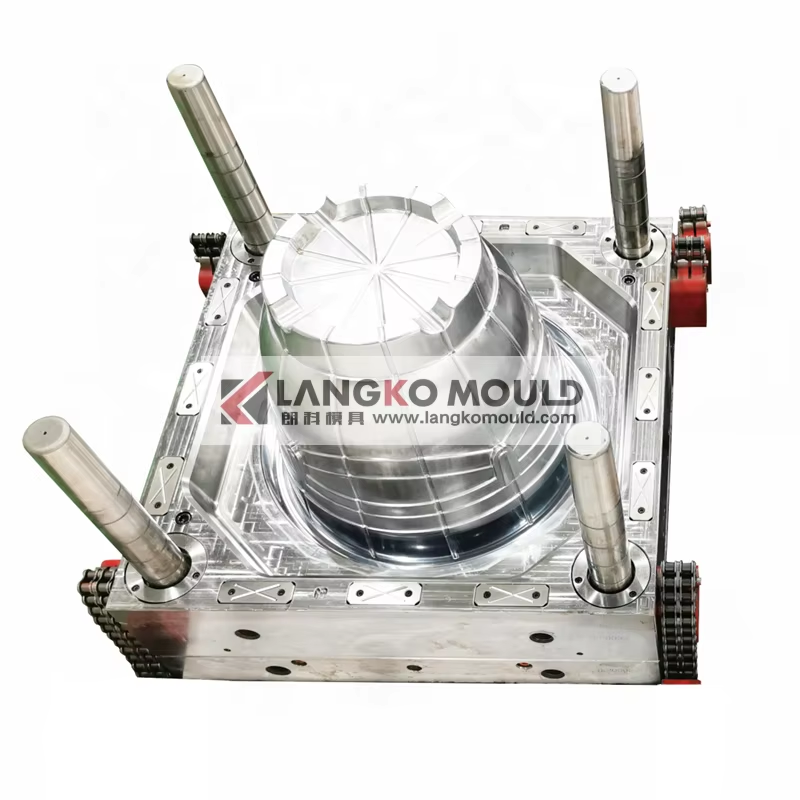

As the saying goes, laymen watch the excitement, experts watch the door. The production requirements of plastic molds are very high. For example, plastic flower pots are generally made of environmentally friendly PP materials. They can be made into a high-end plastic flower pot with a bright surface and then processed by film lamination and printing. However, it is not easy to make a good flower pot. First of all, the quality of the mold must be controlled, including mold design, mold assembly, hot runner and cold runner selection, etc.

1. Assembly of molds

Mold assembly is like assembling a machine. Every part and every screw must be correct. Otherwise, the consequences will be serious. At the very least, it will lead to product defects and affect production. At the worst, it will completely damage the mold and cause it to be scrapped. Therefore, the assembly of the mold must be very meticulous. During the assembly process, the most important thing to pay attention to is the cleaning of the mold, especially the water channel and screw holes, so be sure to blow away the iron filings inside.

2. Hot runner or cold runner

This actually has little impact on mold quality, because hot runners are generally designated brands, especially for some big customers. Foreign famous brands are very good at both quality and after-sales service, so there are generally no major problems with quality. It’s just that the quality of some hot runner brands varies greatly. In order to save costs and gain price advantages, some small companies will use some unreliable heating and conduction accessories, which are prone to problems.

3. Cooling water channel

Anyone who has experience with molds knows how important cooling is to a mold. Due to the increase in raw materials and workers' wages, the profit brought by reducing one second of time in mass production is unimaginable, but speeding up the production cycle will cause the mold temperature to rise. If it is not effectively controlled, the mold will be too hot to form, and even cause the mold to deform and fail. Therefore, excellent water channel design is particularly important, including the arrangement density and diameter of the water channel.

4. Mold maintenance

Mold maintenance mainly refers to maintenance and care during the production process. Molds are like cars. If they are not used for a long time and not maintained, they may be scrapped. Therefore, after each use of the mold, it is necessary to carry out various maintenance, especially the rust prevention of the molding part and the main moving parts. Because the mold needs to be connected to water during the production process, water may get on the mold during the installation or disassembly process, so it is necessary to ensure that the mold is dry, and then apply a layer of oil for protection.

If you have any demand for plastic injection molds, please feel free to contact us, Langko Mould will help you at any time.

Sale Engineer: Lucy

E-mail: sales6@langkomould.com

Wechat / WhatsApp/ Tel: +86 13375867056

86-0576-81122860

86-0576-81122860