PP thinwall box mold mould manufacturer

栏目:MOULD BLOG 发布时间:2024-01-03

Plastic thinwall box have a very good market, as the most people like take out and pack the rest food. And the most plastic thinwall box are made by the injection mold.

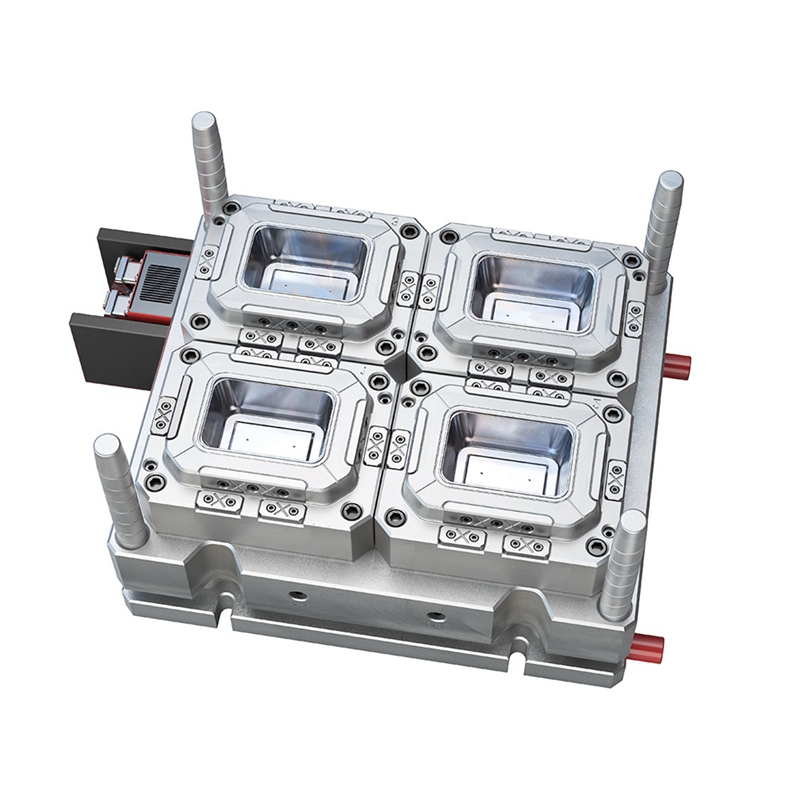

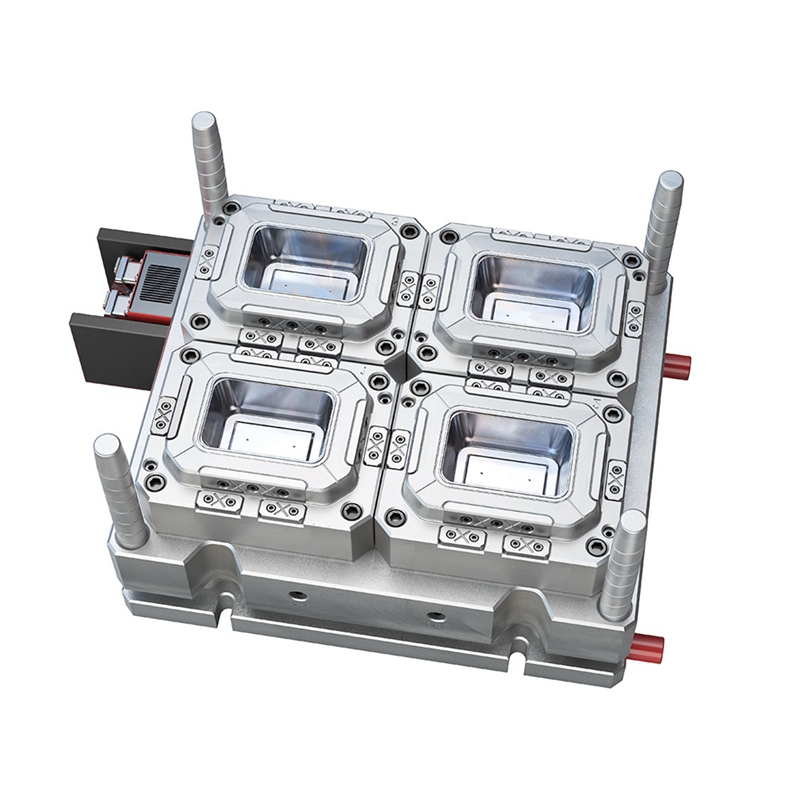

For the injection plastic thinwall box mold, we could make as 1/2/4/8-cavity. Due to the thickness are very thin, around 0.4-0.5mm. So the plasstic thinwall box mold requirement are higher than normal household molds. About the plasstic thinwall box mold steel, we recommend to use S136 or H13 steel. This two steels need vaccum quenching, and the hardness reached to 48-52 or more higher. For the injection system, we use 1 tip hot runner normally for each cavity, sometimes if customer prefer, we also could use valve pin gate hot runner, which can help avoid the deformation of box. But the valve pin gate hot runner costs is higher , so you could choose one your prefer.

The plastic thinwall box mold is better to mass production in high speed injection machine, then the cycle time could be 7-10s for one shot.

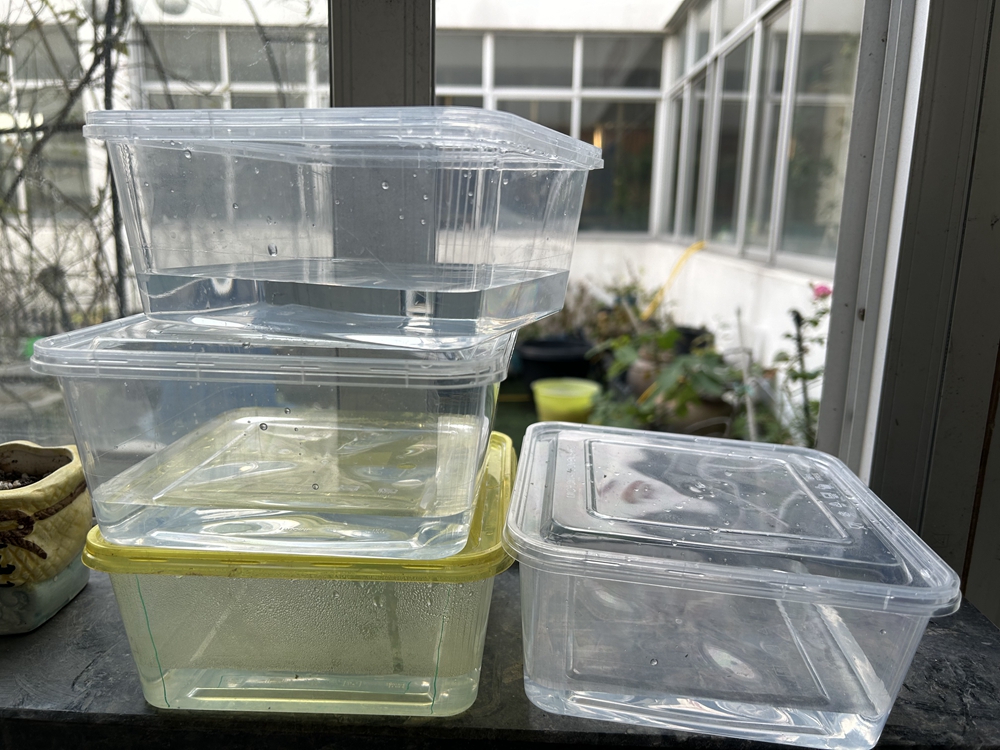

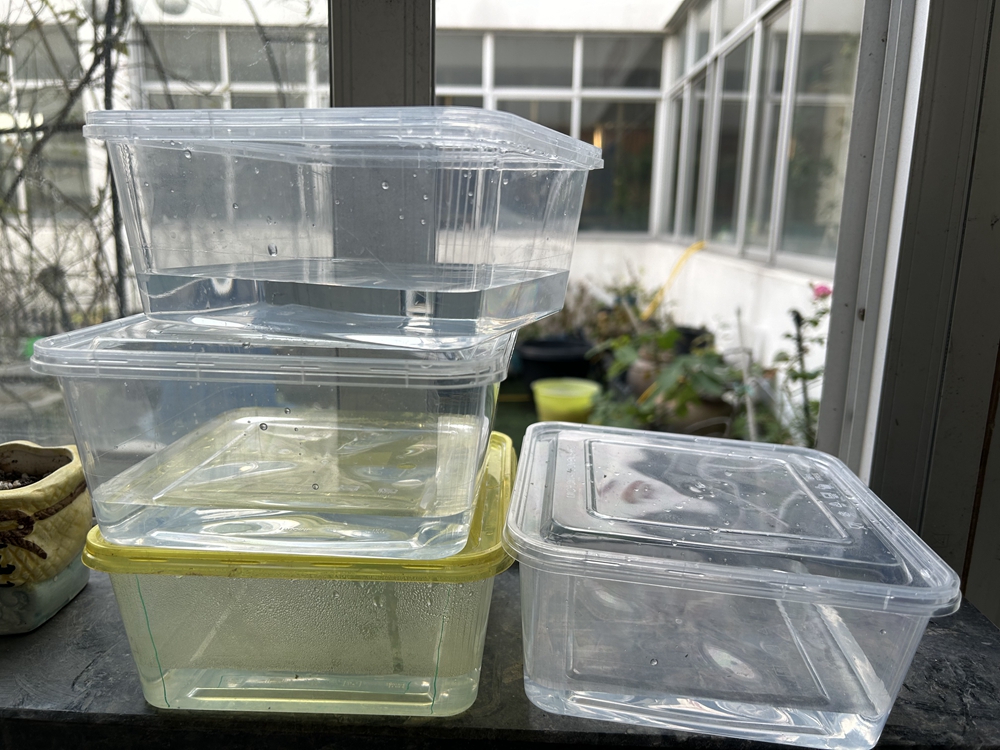

For the box, if you need to put the food inside, then the seal also very important. Then when we make the product design, we will make the good seal design, and when the product come out from the plastic thinwall box mold, we will test the water inside.

If you want to make a plastic thinwall box mold, welcome to send your box sample pictures with your mold requirements.

Our company-LANGKO MOULD will supply a good and competitive price to you.

Contact person: Grace

email: sales2@langkomould.com

For the injection plastic thinwall box mold, we could make as 1/2/4/8-cavity. Due to the thickness are very thin, around 0.4-0.5mm. So the plasstic thinwall box mold requirement are higher than normal household molds. About the plasstic thinwall box mold steel, we recommend to use S136 or H13 steel. This two steels need vaccum quenching, and the hardness reached to 48-52 or more higher. For the injection system, we use 1 tip hot runner normally for each cavity, sometimes if customer prefer, we also could use valve pin gate hot runner, which can help avoid the deformation of box. But the valve pin gate hot runner costs is higher , so you could choose one your prefer.

The plastic thinwall box mold is better to mass production in high speed injection machine, then the cycle time could be 7-10s for one shot.

For the box, if you need to put the food inside, then the seal also very important. Then when we make the product design, we will make the good seal design, and when the product come out from the plastic thinwall box mold, we will test the water inside.

If you want to make a plastic thinwall box mold, welcome to send your box sample pictures with your mold requirements.

Our company-LANGKO MOULD will supply a good and competitive price to you.

Contact person: Grace

email: sales2@langkomould.com

86-0576-81122860

86-0576-81122860