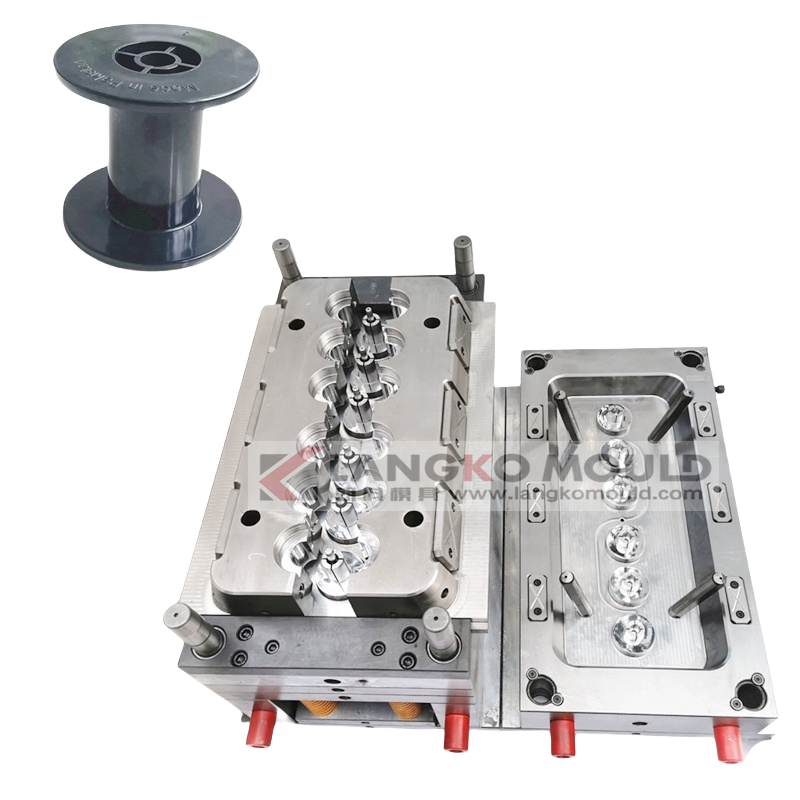

Plastic spool injection mould

栏目:MOULD BLOG 发布时间:2024-10-17

Plastic spool mould is the most common type of injection mould for making plastic spools.popular in textile, wire and cable industries. Plastic spool molds are specially designed for storage solutions that make the winding, unwinding and transportation of cables, wires and other products more convenient and efficient.In this article, we will take an in-depth look at plastic spool molds, including their mold design, manufacturing process, material selection, specific applications, and how to choose a mold supplier that meets your needs.

Components of plastic spool injection mould

Spool mould parts are the most important in key elements of making plastic spool mould.Spool dies typically consist of several basic components, including:Cores

When making a plastic spool mould, one of the most important components is the core. In order for the spool mold to hold the correct amount of material and ensure the winding process goes smoothly, the core must be designed to replicate the shape and size required for the interior of the spool.Cavity

The cavity component shapes the exterior of the plastic spool mould. It defines the product's external dimensions, features, and contours. The cavity is precisely machined to achieve the desired look and function of the reel.Inserts

In some cases, additional inserts may be used in the mold to create specific features or details on the reel. Inserts can be removable components that are placed in the mold to form a specific part of the spool, such as a flange, locking mechanism or specialized structure.Cooling System

The cooling system plays a vital role in the entire mold, including cold runners and inserts, which effectively manage and regulate the temperature throughout the molding process. It helps solidify the molten plastic and maintains stable cooling to achieve the best part quality.Ejector System

The ejector system helps remove the molded plastic spool from the mold after it has solidified. The ejector system may include ejector pins, ejector plates, or other structures to eject the cable reel.Application of Plastic spool

Plastic wire reel is used in various industries, it is a cylindrical device for storing various types of materials. As the demand for neat packaging and transportation of materials in modern manufacturing industry increases, the demand for plastic stool mould also increases, and has become an essential tool for packaging and transportation companies to reel various materials.Wire and Cable Industry

Plastic stools are widely used in the wire and cable industry and are the preferred solution for storing and winding various types of wires. They are used to wind and store different types of wires, including electrical wires, electrical cables, and fiber optic cables.Textile Industry

In the textile industry, plastic spools are ideal for winding and storing cables, yarns and fibers. They are small and lightweight for easy transportation and storage, while also being strong enough to withstand frequent use.Crafts & Decoration

The carefully designed plastic spools mold ensures that the finished plastic spool is in perfect shape and becomes an indispensable item in crafts and DIY projects due to its durability and flexibility. It can be used to wrap and store decorative materials such as ribbons, lace or string.Advantages of Plastic spools Mould

In this era of efficiency and time saving, plastic spool mould have become a popular choice in the cable management process.Efficiency and time saving:

Plastic spools produced by injection molding have high consistency and uniformity, making them suitable for automated processes, ensuring smooth and efficient cable winding and unwinding, saving cable production, installation and maintenance time. In addition to consistency, these plastic spools are also lightweight and durable, providing excellent protection for the cables inside.

Improve organization:

Plastic spools are excellent organizational tools that can neatly roll up cables for easy storage and classification of different types of cables. This orderly storage method can greatly simplify the cable management process and make inventory control easier.Improve accessibility:

With the help of plastic spools as tools, cables wrapped around the reels can be easily deployed and retrieved. This simplifies tasks such as installing new cables, maintaining existing cables, or removing old cables.

Sale Engineer: Luna

E-mail: market@langkomould.com

Wechat / WhatsApp/ Tel: +86-13306762335

Facebook: https://www.facebook.com/langkomould

Website: https://www.langkomould.com/

TAIZHOU HUANGYAN LANGKO MOULD CO.,LTD

ADD: NO.345, XINJIANG ROAD, XINQIAN STREET, HUANGYAN, 318020, TAIZHOU, ZHEJIANG, CHINA

Next:Nothing

86-0576-81122860

86-0576-81122860