More Than Just a Bucket: The Engineering Marvel of Injection Molding

栏目:MOULD BLOG 发布时间:2025-10-30

Look around your home, garage, or worksite. Chances are, you'll see a plastic bucket. It's one of those humble, ubiquitous items we often take for granted. But have you ever stopped to wonder how it's made? That perfectly symmetrical, seamless, and incredibly durable bucket is a masterpiece of modern manufacturing, born from a process called injection molding and a precision plastic injection bucket mold.

Today, we're diving deep into the world of injection molding by using a simple bucket as our case study.

The Magic of Injection Molding

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. For our bucket, that material is typically polyethylene (PE) or polypropylene (PP)—plastics chosen for their excellent toughness, chemical resistance, and flexibility. This is all made possible by the custom plastic injection bucket mold.

The process is fast, efficient, and perfect for creating high volumes of identical items with incredible precision. Here's how it works:

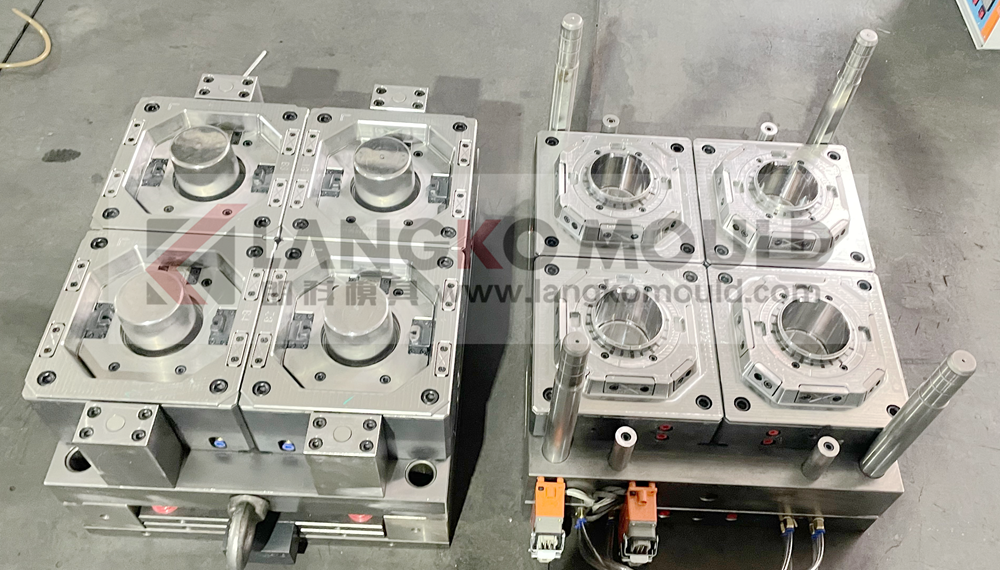

The plastic injection bucket Mold: It all starts with a heavy, steel mold. One half forms the bucket's interior, and the other forms its exterior. The design and craftsmanship of this plastic injection bucket mold are critical—it's a negative of the final bucket.

Injection: Plastic pellets are fed into a heated barrel, where they are melted into a liquid. This molten plastic is then forcibly injected into the cavity of the closed plastic injection bucket mold.

Cooling: The plastic inside the plastic injection bucket mold is allowed to cool and solidify. As it cools, it takes the exact shape of the mold cavity.

Ejection: Once solid, the two halves of the plastic injection bucket mold open, and ejector pins gently push the brand-new bucket out. The plastic injection bucket mold then closes, and the cycle repeats—every 30 to 60 seconds!

Why Injection Molding is Perfect for Buckets

So, why is this method and the plastic injection bucket mold the gold standard for bucket manufacturing?

Seamless & Watertight: Unlike buckets made from other methods, injection-molded buckets from a plastic injection bucket mold are monolithic. They have no seams, which means no weak points and no risk of leaking.

Incredible Strength: The process and the plastic injection bucket mold allow for uniform wall thickness. This precise control from the plastic injection bucket mold ensures the bucket is strong and durable. The design of the plastic injection bucket mold is key to this strength.

Contact person: Grace

Contact person: Grace

86-0576-81122860

86-0576-81122860