From a Summer Ice Bucket to the Precision Behind It: The Role of the Plastic Injection Ice Bucket

栏目:MOULD BLOG 发布时间:2025-10-23

A transparent ice bucket filled with drinks and ice is a staple of summer parties, family gatherings, or a quiet afternoon alone.

We appreciate its crystal-clear appearance, comfortable handle, and snug-fitting lid, but have you ever wondered how such a product is mass-produced with high precision?

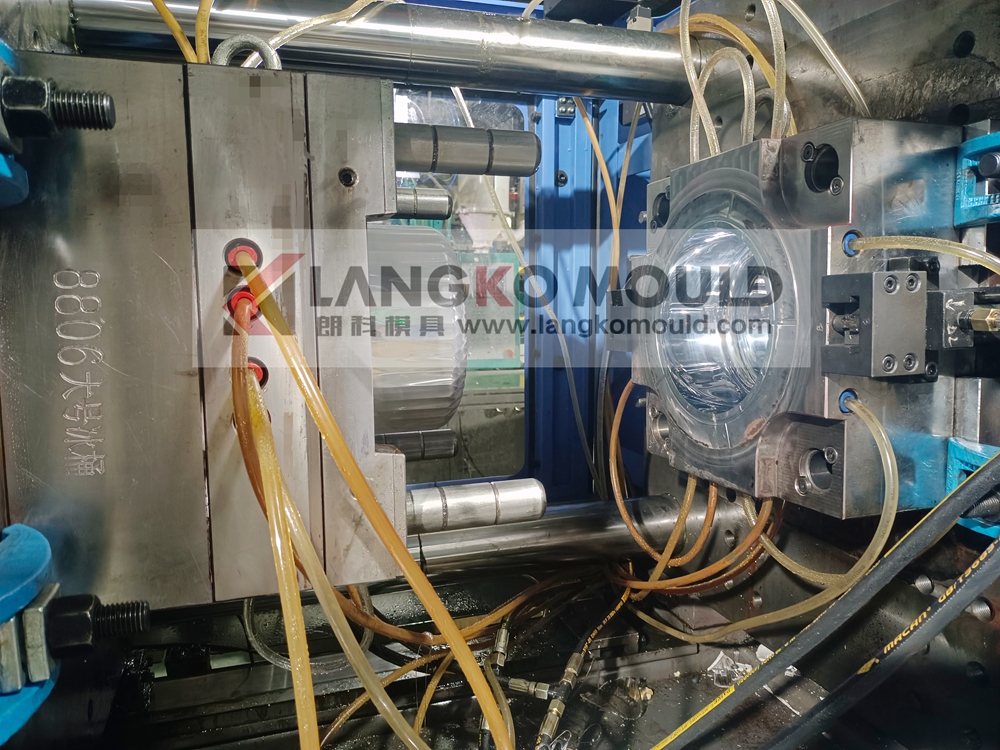

The answer lies in the plastic injection ice bucket mold.

Why is Injection Molding Ideal for Ice Buckets?

High Efficiency: A single plastic injection ice bucket mold can produce a complete bucket or lid in one cycle (typically tens of seconds to two minutes), making it ideal for large-scale production.

Design Flexibility: Complex structures like handles, clasps, and threads can be formed in one shot with consistent quality.

Excellent Surface Finish: Especially for transparent or colored ice buckets, injection molding delivers a smooth, mirror-like finish.

Key Design Elements of an Ice Bucket Mold

1. Parting Line Selection: The parting line is usually placed at the rim of the bucket, making the seam less visible and facilitating demolding.

2. Ejection System: Ice buckets molds often use a ejector pins + ejector plate combination, sometimes assisted by air ejection, to ensure smooth release.

3. Cooling System: Precision cooling channels inside the plastic injection ice bucket mold act like a built-in air conditioner, ensuring even cooling and shorter cycle times.

4. Venting Design: Venting slots are added at the parting line or insert seams to prevent defects like burning or short shots caused by trapped air.

Mold Materials & Surface Treatment

Steel Selection: Transparent ice buckets often require corrosion-resistant mirror polish steels (e.g., S136) to maintain a high-gloss finish over long production runs.

Surface Treatment: The cavity is often mirror-polished or chrome-plated to improve release performance and extend the plastic injection ice bucket mold's lifespan.

Challenges in Production

Material Choice: Common materials include GPPS (high clarity, low cost, but brittle) or PC (tough, impact-resistant, but more expensive).

Process Control: Parameters like injection speed, pressure, and cooling time must be precisely controlled to avoid defects like sink marks or bubbles.

Future Trends: Smarter & More Efficient

In-Mold Labeling (IML): Allows for integrated, durable graphics during the injection process.

Automation & High-Speed Molding: Using robotics for full automation increases efficiency.

Smart Molds: Sensors embedded in the plastic injection ice bucket mold enable real-time monitoring and predictive maintenance.

A simple ice bucket is the result of sophisticated mold engineering and manufacturing.

The next time you reach for a cool drink, you might appreciate this everyday object a little more—thanks to the plastic injection ice bucket mold behind it.

86-0576-81122860

86-0576-81122860