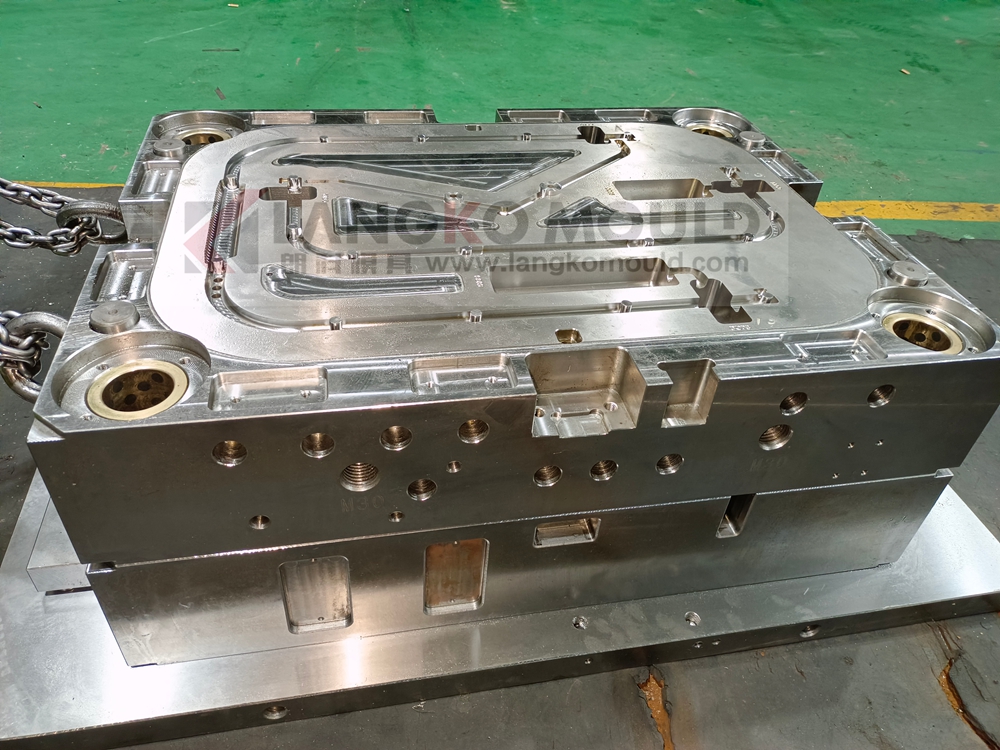

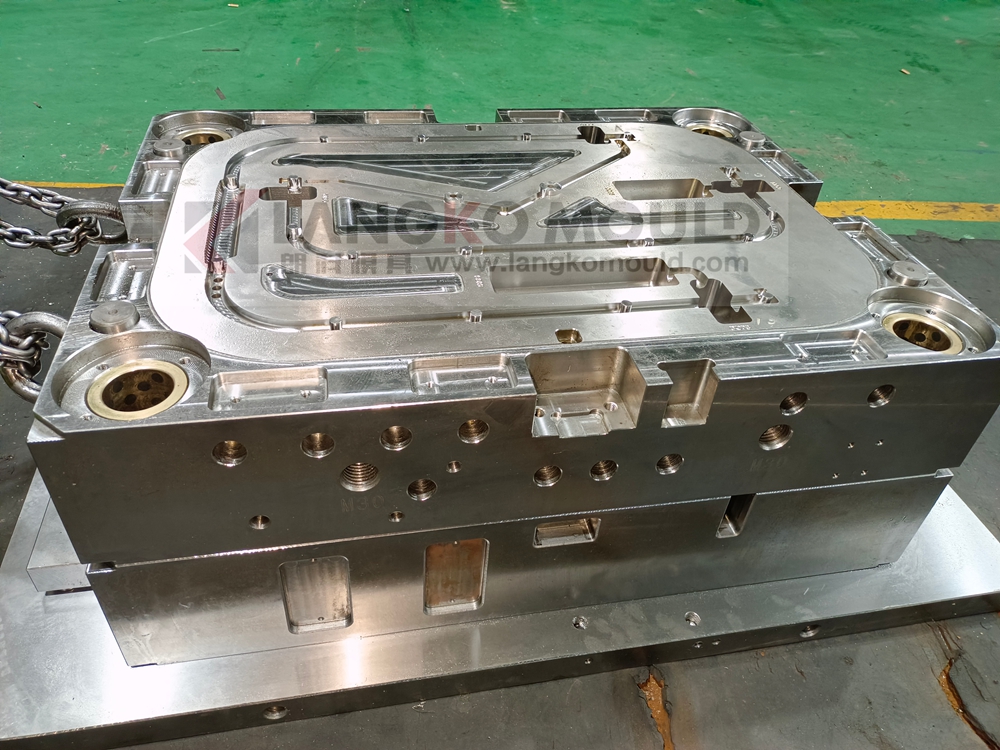

Huangyan rich experience multi cavity plastic injection gas assisted handle mold maker

栏目:MOULD BLOG 发布时间:2025-06-24

Plastic injection gas assisted handle mold are more popular in market, due to inner is empty could save some material costs. But how is this mold make? Let’s browse the blog.

Gas assisted is a new type injection technical. For the traditional injection molds, if the structure is complex, it is will have some problem in surface shrinkage, overweight problem. But the gas assistant could solve it. Gas assisted handle mold technical is when the plastic into the mold cavity , the air will come , like blow the balloon.With its uniform pressure, the gas pushes the plastic melt to continue filling the remaining space of the mold and forms a hollow structure inside the product. This unique forming method not only significantly improves product quality but also optimizes production efficiency.

But for the gas assisted the air tunnel, gate size and position, mold structure and steel are very important.

For the gas assisted handle mold,a reasonable airway distribution can ensure that high-pressure gas is evenly diffused in the cavity, thereby promoting the plastic melt to precisely fill every corner of the mold. We will carefully plan the airway direction based on the outline and functional requirements of the handle. Usually, the airway is set at the part of the handle where the wall thickness is larger and the force is smaller. This can not only ensure that the gas can smoothly push the plastic melt, but also will not affect the mechanical properties of the handle.

For the gate position and size, in the design of the handle mold, the selection of the gate position should comprehensively consider the flow characteristics of the plastic melt, the pushing direction of the gas, and the appearance requirements of the handle. If the gate position is improper, it may lead to uneven filling of the plastic melt, which in turn affects the gas-assisted effect and even leaves obvious weld marks on the surface of the product. Meanwhile, the precise control of the gate size is also of vital importance. It directly affects the injection speed and pressure of the plastic melt and influences the stability of the entire injection molding process.

For the gas assisted handle mold steel, due to the fact that the mold needs to withstand the high pressure of the plastic melt and the secondary pressure of the gas during the gas-assisted injection molding process, higher requirements are put forward for the material and structural strength of the mold. Molds are usually made of high-strength and highly wear-resistant steel, such as H13,S136,2344 steel etc. Moreover, in the design of the mold structure, reinforcing ribs and support structures have been added to enhance the overall rigidity of the mold, ensuring that it can still maintain high precision and produce qualified handle products under long-term and high-pressure production conditions.

Gas assisted handle mold advantage:

1. Increase the quality of the product

2. Reduce the material costs

3. Enhance productivity

Injection gas-assisted handle molds, with their unique technical advantages, have brought a qualitative leap to the production of handle products. From the ingenious design conception to the efficient and high-quality production process, and then to the wide range of application fields, all demonstrate the strong vitality of this technology. With the continuous advancement of technology, it is believed that gas-assisted injection molding technology will continue to innovate and develop in the future, bringing more surprises to the plastic products industry.

Welcome to contact Langko Mould if you have any interests in gas assisted handle mold.

Contact person: Grace

Gas assisted is a new type injection technical. For the traditional injection molds, if the structure is complex, it is will have some problem in surface shrinkage, overweight problem. But the gas assistant could solve it. Gas assisted handle mold technical is when the plastic into the mold cavity , the air will come , like blow the balloon.With its uniform pressure, the gas pushes the plastic melt to continue filling the remaining space of the mold and forms a hollow structure inside the product. This unique forming method not only significantly improves product quality but also optimizes production efficiency.

But for the gas assisted the air tunnel, gate size and position, mold structure and steel are very important.

For the gas assisted handle mold,a reasonable airway distribution can ensure that high-pressure gas is evenly diffused in the cavity, thereby promoting the plastic melt to precisely fill every corner of the mold. We will carefully plan the airway direction based on the outline and functional requirements of the handle. Usually, the airway is set at the part of the handle where the wall thickness is larger and the force is smaller. This can not only ensure that the gas can smoothly push the plastic melt, but also will not affect the mechanical properties of the handle.

For the gate position and size, in the design of the handle mold, the selection of the gate position should comprehensively consider the flow characteristics of the plastic melt, the pushing direction of the gas, and the appearance requirements of the handle. If the gate position is improper, it may lead to uneven filling of the plastic melt, which in turn affects the gas-assisted effect and even leaves obvious weld marks on the surface of the product. Meanwhile, the precise control of the gate size is also of vital importance. It directly affects the injection speed and pressure of the plastic melt and influences the stability of the entire injection molding process.

For the gas assisted handle mold steel, due to the fact that the mold needs to withstand the high pressure of the plastic melt and the secondary pressure of the gas during the gas-assisted injection molding process, higher requirements are put forward for the material and structural strength of the mold. Molds are usually made of high-strength and highly wear-resistant steel, such as H13,S136,2344 steel etc. Moreover, in the design of the mold structure, reinforcing ribs and support structures have been added to enhance the overall rigidity of the mold, ensuring that it can still maintain high precision and produce qualified handle products under long-term and high-pressure production conditions.

Gas assisted handle mold advantage:

1. Increase the quality of the product

2. Reduce the material costs

3. Enhance productivity

Injection gas-assisted handle molds, with their unique technical advantages, have brought a qualitative leap to the production of handle products. From the ingenious design conception to the efficient and high-quality production process, and then to the wide range of application fields, all demonstrate the strong vitality of this technology. With the continuous advancement of technology, it is believed that gas-assisted injection molding technology will continue to innovate and develop in the future, bringing more surprises to the plastic products industry.

Welcome to contact Langko Mould if you have any interests in gas assisted handle mold.

Contact person: Grace

Next:Nothing

86-0576-81122860

86-0576-81122860