About thin wall mold

栏目:MOULD BLOG 发布时间:2024-09-03

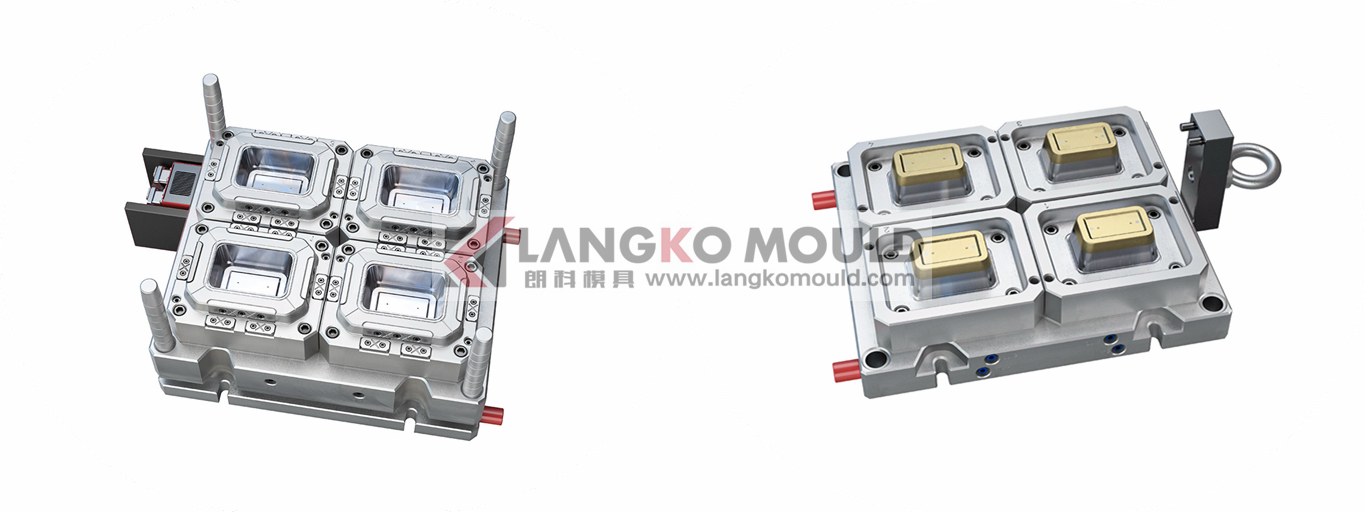

What Is Thin Wall Mold?

Thin wall mold refer to molds with a wall thickness of less than 1mm, specifically designed for producing thin wall structural components or products.Due to their high precision and efficiency, thin wall molds enable high-speed and high-accuracy production.

They are suitable for manufacturing plastic containers, shells, caps, cups, plates, and other flat or three-dimensional thin wall structures.

Compared to standard molds, thin wall molds typically have more complex structures and impose stricter requirements on processing technology and equipment.Control of wall thickness is very stringent for thin-wall molds. Ideally, the wall thickness should be between 0.5mm and 1.0mm.

Why Choose Thin wall Mold?

Thin-wall molds, with their high precision, complexity, and efficiency, can effectively reduce material waste, improve production efficiency, and lower production costs during the manufacturing process.the design and manufacture of thin-wall mold are meticulously optimized, enabling the rapid and efficient production of required parts.This not only shortens the production cycle but also enhances production efficiency, resulting in significant cost savings for companies over the long term.Thin-wall molds are ideal for many fast-moving consumer packaging, such as milk tea cups, disposable plastic cups, disposable fast food boxes, etc.

Due to the specific materials required in the manufacturing process of thin wall mold, it is essential to consider the hardness, wear resistance, and good machinability of the chosen steel.

Here are some types of steel suitable for thin wall molds:

· P20 Steel

P20 steel is a chromium-nickel alloy steel known for its excellent machinability and structural stability.

It also has high hardness and strength, making it an ideal choice for manufacturing thin wall molds.

· S136 Steel

S136 steel is a type of stainless steel with extremely high corrosion resistance.

In the production of thin wall mold, it effectively prevents surface corrosion of the components, ensuring the longevity and quality of the mold.

It is frequently used for making high-precision molds, meeting the requirements for high accuracy and long service life of thin wall molds.

If you need to customize a thin wall mold,please contact us.LANGKO MOULD will be your most reliable injection mold supplier!

Whether it’s thin-wall plastic boxes,cups,or buckets,LANGKO MOULD can provide you with the most cost-effective manufacturing solutions,ensuring that your product quality and production efficiency are optimized.

Sale Engineer: Luna

E-mail: market@langkomould.com

Wechat / WhatsApp/ Tel: +86-13306762335

Facebook: https://www.facebook.com/langkomould

Website: https://www.langkomould.com/

TAIZHOU HUANGYAN LANGKO MOULD CO.,LTD

ADD: NO.345, XINJIANG ROAD, XINQIAN STREET, HUANGYAN, 318020, TAIZHOU, ZHEJIANG, CHINA

86-0576-81122860

86-0576-81122860