About Helmet Mould

栏目:MOULD BLOG 发布时间:2024-09-11

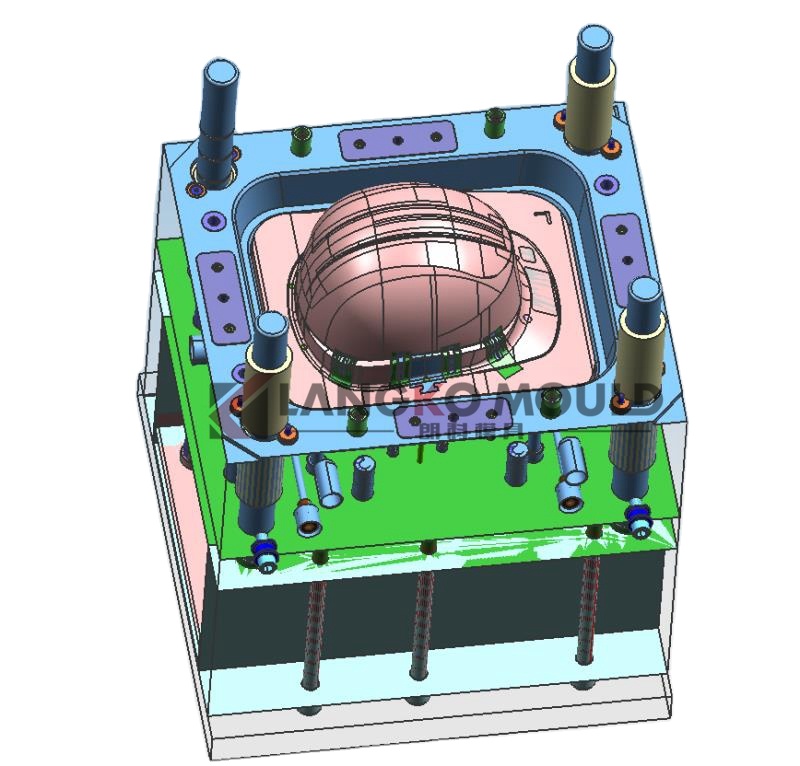

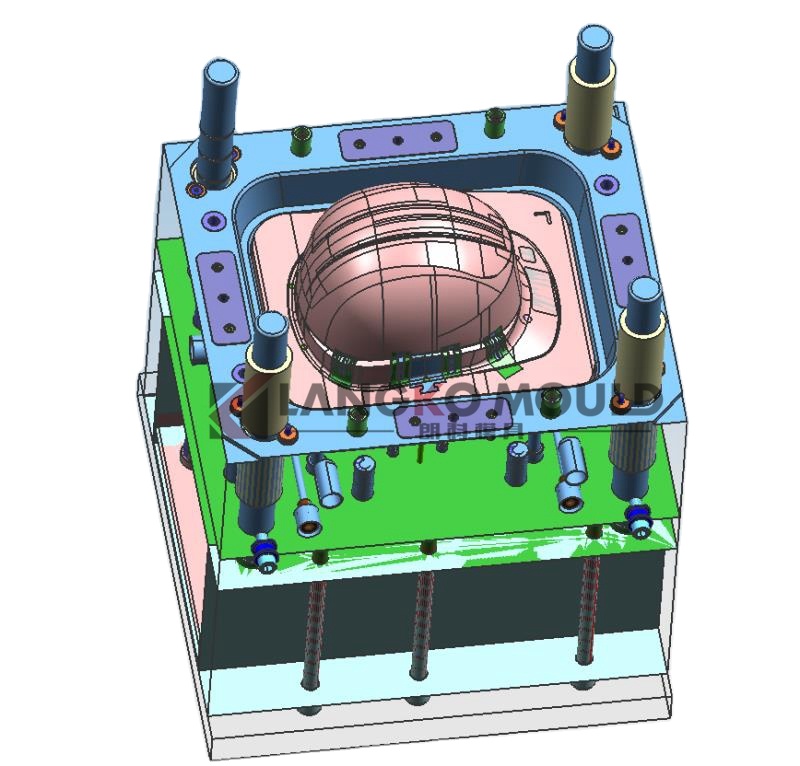

Plastic helmet mold is the basic tool for manufacturing helmets.Helmet molds are usually made of durable materials such as steel or aluminum,these materials can withstand high temperatures and pressures during the production process.The mold is divided into two parts: the core and the cavity. When these two parts are combined, they create the complete from the helmet.The design and manufacture of the helmet mold both affect the final quality of the helmet. It ensures that the helmet has the right size and shape to provide maximum comfort. It can also design various safety features and design elements to ensure that the helmet provides the best protection for the wearer.

First, at the beginning of the design, it is necessary to consider the target users, their needs, and the environment in which they are used. Basically, users who use helmets are in some dangerous environments, so safety performance must be taken into account. Sketches are usually drawn first to visualize the ideas and provide a preliminary design as a basis for work.

Next, the sketch design is converted into a 3D model using computer-aided design (CAD) software. This includes the shape, size, contours of the helmet design, and details of features such as ventilation slots and connection points.

Once the digital model is completed, a prototype is usually created using 3D printing technology to allow the design team to evaluate the physical properties of the plastic helmet mould design. Test factors such as comfort, fit, and aerodynamics. If any defects and areas for improvement are found at this stage, the design is modified and a new prototype is created. This cycle continues until a satisfactory design is obtained.

Manufacyuring process of plastic helmet mould

First,According to the helmet design and size required, use 3D printing for models.The models usually made of materials such as resin or metal.

Next,create mould cavity and corn.place the main model in the box.then add silicone or other rubber compound molding materials.When the material solidifies,it will from an exact replica of the master model shape. This forms the main part of the mold, called the mold cavity,The hardened mold material is separated from the master pattern to form the core.

Prepare the corn and cavity,now we can make real plastic helmet mould.the step usually done by heating a durable mateial such as steel or aluminum until it becomes liquid.then inject cavity of mold to finish.When the solidifies,it will from an exact copy of the original model.

After the finished,The newly made plastic helmet mold undergo finishing.This includes removing excess material and grinding the surface. Depending on the design and mold material, processes such as grinding, polishing, and buffing may be used.

Quality inspection is the final step of manufacture process. This involves checking the mold to ensure it matches the original design accurately. It includes checking dimensions, verifying shape, and confirming that all features have been formed correctly. Any defects or errors found at this stage are corrected and the mold may be recast if necessary.

Accuracy maintenance:Mold design and production process It’s very important to keep size precision.To solve this problem,we can use CAD to design,and use CNC machine to production to improve the accuracy and precision of plastic helmet molds.Regular inspections and quality checks can also kelp maintain accuracy.

Material selection:Choosing the right material for the mold is very important.The material must be durable enough to withstand the high pressures and high temperature of the helmet manufacturing process.To address this issue,material testing should be conducted prior to mold fabrication to help determine the best material for a particular helmet type.

Incorporating Design Features:Certain complex elements such as vents such as vent holes,visor attachments and recesses for internal fill locations need to be incorporated when performing helmet mold design but may be difficult to incorporate yhese features during the design phase.

Application of Plastic helment mould

Plastic helmet mould is crucial tools in the manufacturing process of helmets,which have wide-ranging applications across numerous sectors.Here are a few ley applications of helmet moulds.

Accuracy maintenance

Plastic helmet moulds are used in creating helmets for various industrial and construction jobs. These helmets are designed to protect workers from falling objects, bumps, and electrical shocks. They often have mounts for attaching accessories like headlamps or face shields.

Motorcycle Helmets

One of the most common applications of plastic helmet mould is the production of motorcycle helmets.These helmets usually use hardness plastic shell that is moldes to help people have traffic accident.

The Design Process of a Helmet Mould

The plastic helmet mold design process is a multi-step process through which the design concept is transformed into a tangible product that plays an important role in ensuring the safety and comfort of helmet users.First, at the beginning of the design, it is necessary to consider the target users, their needs, and the environment in which they are used. Basically, users who use helmets are in some dangerous environments, so safety performance must be taken into account. Sketches are usually drawn first to visualize the ideas and provide a preliminary design as a basis for work.

Next, the sketch design is converted into a 3D model using computer-aided design (CAD) software. This includes the shape, size, contours of the helmet design, and details of features such as ventilation slots and connection points.

Once the digital model is completed, a prototype is usually created using 3D printing technology to allow the design team to evaluate the physical properties of the plastic helmet mould design. Test factors such as comfort, fit, and aerodynamics. If any defects and areas for improvement are found at this stage, the design is modified and a new prototype is created. This cycle continues until a satisfactory design is obtained.

Manufacyuring process of plastic helmet mould

First,According to the helmet design and size required, use 3D printing for models.The models usually made of materials such as resin or metal.

Next,create mould cavity and corn.place the main model in the box.then add silicone or other rubber compound molding materials.When the material solidifies,it will from an exact replica of the master model shape. This forms the main part of the mold, called the mold cavity,The hardened mold material is separated from the master pattern to form the core.

Prepare the corn and cavity,now we can make real plastic helmet mould.the step usually done by heating a durable mateial such as steel or aluminum until it becomes liquid.then inject cavity of mold to finish.When the solidifies,it will from an exact copy of the original model.

After the finished,The newly made plastic helmet mold undergo finishing.This includes removing excess material and grinding the surface. Depending on the design and mold material, processes such as grinding, polishing, and buffing may be used.

Quality inspection is the final step of manufacture process. This involves checking the mold to ensure it matches the original design accurately. It includes checking dimensions, verifying shape, and confirming that all features have been formed correctly. Any defects or errors found at this stage are corrected and the mold may be recast if necessary.

helmet mould design and manufacture

It’s the complex process to produce high quality helmets. Involves two key stages:plastic helmet mould design and produce.However,It’s uneasy to finish this task,and need face many difficult.Accuracy maintenance:Mold design and production process It’s very important to keep size precision.To solve this problem,we can use CAD to design,and use CNC machine to production to improve the accuracy and precision of plastic helmet molds.Regular inspections and quality checks can also kelp maintain accuracy.

Material selection:Choosing the right material for the mold is very important.The material must be durable enough to withstand the high pressures and high temperature of the helmet manufacturing process.To address this issue,material testing should be conducted prior to mold fabrication to help determine the best material for a particular helmet type.

Incorporating Design Features:Certain complex elements such as vents such as vent holes,visor attachments and recesses for internal fill locations need to be incorporated when performing helmet mold design but may be difficult to incorporate yhese features during the design phase.

Application of Plastic helment mould

Plastic helmet mould is crucial tools in the manufacturing process of helmets,which have wide-ranging applications across numerous sectors.Here are a few ley applications of helmet moulds.

Accuracy maintenance

Plastic helmet moulds are used in creating helmets for various industrial and construction jobs. These helmets are designed to protect workers from falling objects, bumps, and electrical shocks. They often have mounts for attaching accessories like headlamps or face shields.

Motorcycle Helmets

One of the most common applications of plastic helmet mould is the production of motorcycle helmets.These helmets usually use hardness plastic shell that is moldes to help people have traffic accident.

Rescue Helmets

Rescue helmets are necessary safety equipment for emergency responders. Plastic helmet mold are carefully designed to withstand strong impacts and provide excellent protection while maintaining wearing comfort.This ensures that the final helmet product is lightweight,durable and able to absorb impact forces.

How to choose a helmet mould supplier

LANGKO MOULD have over 17 years experience to making plastic helmet mould,Using injection molding technology, we design and develop molds and injection mold high-quality helmet products according to your requirements.welcome to inquiry and visit our company.

Sale Engineer: Luna

E-mail: market@langkomould.com

Wechat / WhatsApp/ Tel: +86-13306762335

Facebook: https://www.facebook.com/langkomould

Website: https://www.langkomould.com/

TAIZHOU HUANGYAN LANGKO MOULD CO.,LTD

ADD: NO.345, XINJIANG ROAD, XINQIAN STREET, HUANGYAN, 318020, TAIZHOU, ZHEJIANG, CHINA

Next:Nothing

86-0576-81122860

86-0576-81122860