DFM - What is the DFM?

栏目:MOULD BLOG 发布时间:2024-10-17

DFM - What is the DFM?

DFM - Design for Manufacturing

It focuses on the interrelationships between the physical characteristics of the product itself and the components of the manufacturing system, and uses it in product design in order to integrate the entire manufacturing system for overall optimization and to make it more standardized, so that we could reduce the costs, shorten production time, and improve product manufacturability and efficiency.

Normally, We will make a DFM report, for a more comprehensive presentation of DFM.

DFM report is one of the most important steps. It's a bridge between product developers and mould makers.

DFM is a highly effective way of communicating in the mould industry, and it also shows extraordinary value in production and manufacturing. A comprehensive DFM report of mould manufacturing project will be the first step to success.

In the plastic injection mould industry, a comprehensive DFM report ensures that communication about mould and product between customers and mould makers is smoother. DFM report could help to resolve the problem about mould and product more efficiently. Whether you are a mould maker or a customer, the more potential problems you foresee, the less risk you have in the manufacturing process. It can help reduce a lot of trial and error costs and shorten the mould making time. And correspondingly, the fewer problems there are on the mold, the higher the quality of the mould you will get. Therefore, DFM is an indispensable step in the mould manufacturing process.

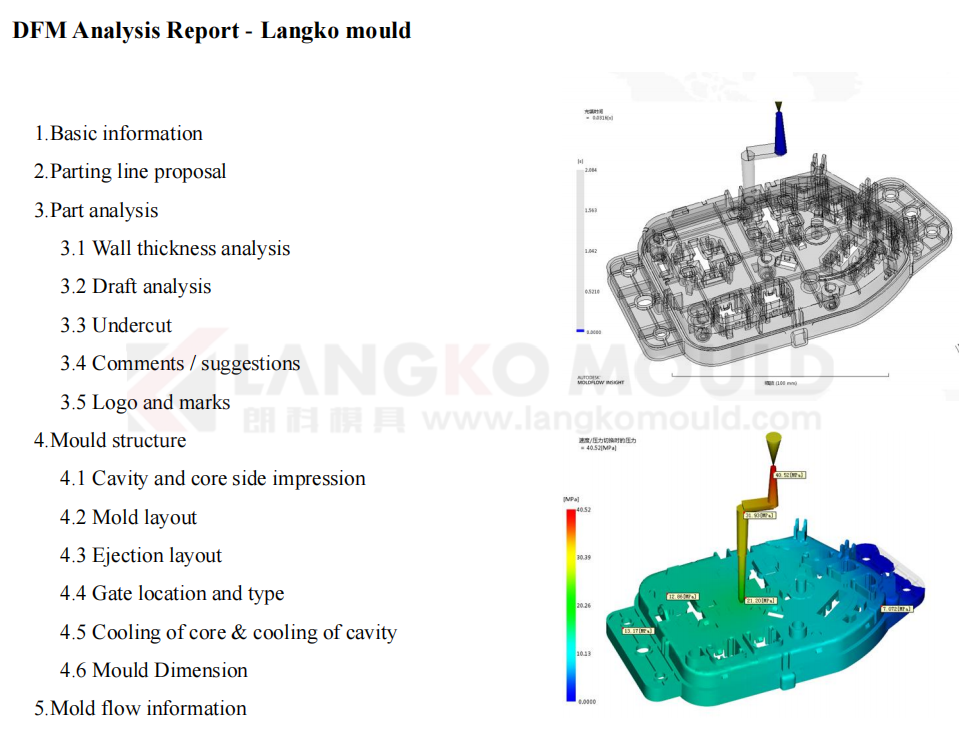

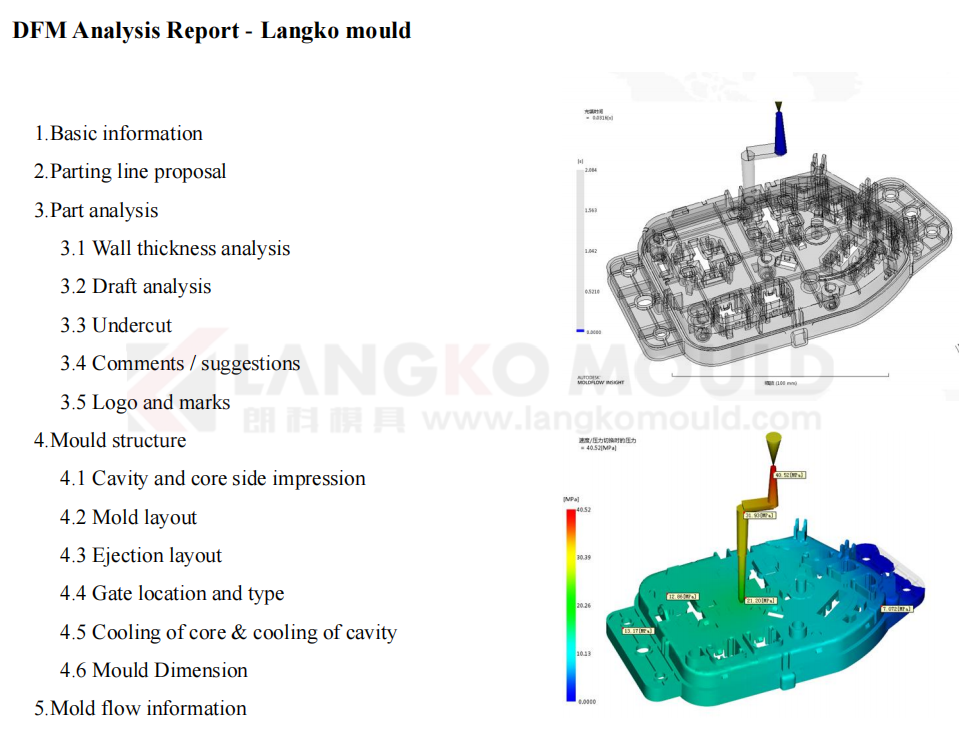

So, in mould industry, what does a common DFM report contain?

So, in mould industry, what does a common DFM report contain?

1. Base information

It mainly includes mould steel, cavity, type, product plastic material...

2. Parting line proposal

3. Product analysis

It mainly includes Wall thickness analysis, Draft angle analysis, Undercut, Logo and Marks...

4. Mould structure

It mainly includes Layout of cavity and core, Layout of ejector, Gate location and type, Cooling line of cavity and core, Dimensions of different parts...

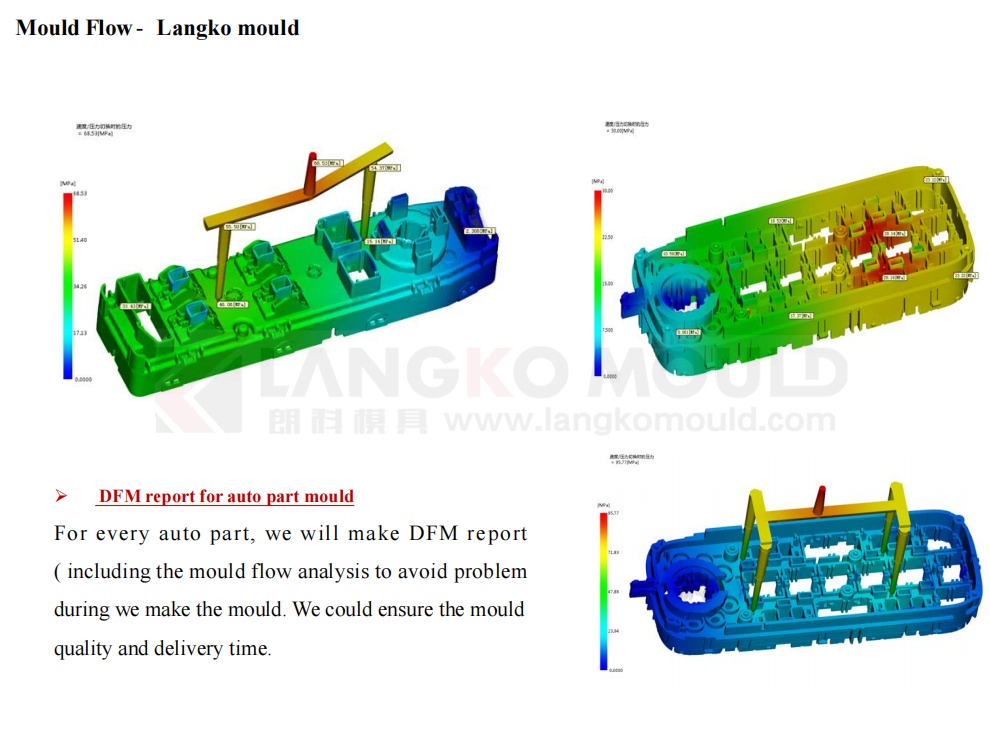

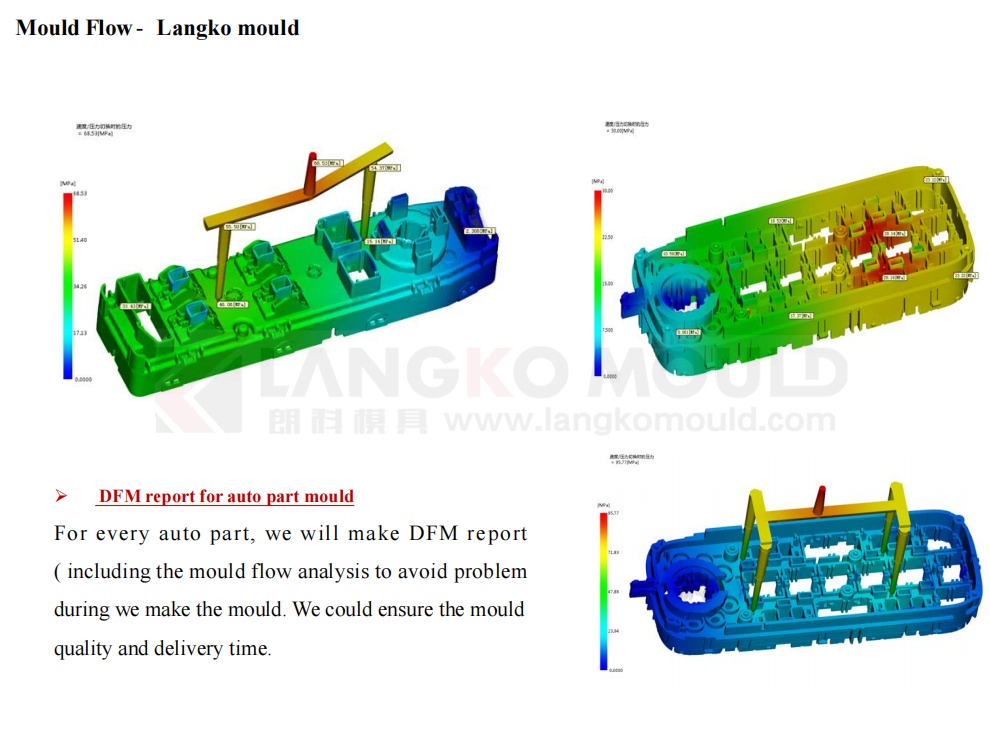

5. Mould flow

Simulation of injection molding, simulating the process of molding and injection, and obtaining some data results. Through these results, we can evaluate the feasibility of the mould plan and improve the mould design plan and plastic part and product design plan.

In these processes, our designers and engineers will offer their professional suggections according to the customized product if they find something unreasonable or there are some parts that can be optimized. Langko mould will note and explain these things on the DFM report so that customer could more easily understand and give their feedback. Langko mould will try to optimize mould and product design according to the customers' requirements. A great design is the first step to make a high quality mould. Although there may be many unknown conditions in mould making. But Langko mould will carefully do every step we can control.

Langko mould is a professional plastic injection mould factory with 17 years experience. We have our own professional designers and engineers. So whether you want to customize your own moulds or just a DFM report to check your mould or product design, or you are just interested in DFM and want to learn more about DFM, please feel free to contact me!

Langko mould is a professional plastic injection mould factory with 17 years experience. We have our own professional designers and engineers. So whether you want to customize your own moulds or just a DFM report to check your mould or product design, or you are just interested in DFM and want to learn more about DFM, please feel free to contact me!

Sale Engineer: Yulia

E-mail: sales6@langkomould.com

Wechat / WhatsApp/ Tel: +86 13375867056

Facebook: https://www.facebook.com/langkomould

Website: https://www.langkomould.com/

TAIZHOU HUANGYAN LANGKO MOULD CO.,LTD

ADD: NO.345, XINJIANG ROAD, XINQIAN STREET, HUANGYAN, 318020, TAIZHOU, ZHEJIANG, CHINA

86-0576-81122860

86-0576-81122860