Different injection system for the crate mold

栏目:MOULD BLOG 发布时间:2022-09-20

Crate have many use way: logistic, storage.

Crate, also could called logistics box.It is widely used in machinery, automobile, household appliances, light industry, electronics and other industries, can withstand acid and alkali, oil resistance, non-toxic and tasteless, can be used to store food, etc., easy to clean, easy to turn over parts, stacked neatly, easy to manage. Its reasonable design, excellent quality, suitable for the factory logistics in the transportation, distribution, storage, circulation processing.

The crate was made by injection machine. Do you know the injection system for the crate mold?

There have two injection system for the crate mold: hot runner and cold runner. But hot runner has two kinds: hot runner big gate or hot runner valve pin gate.

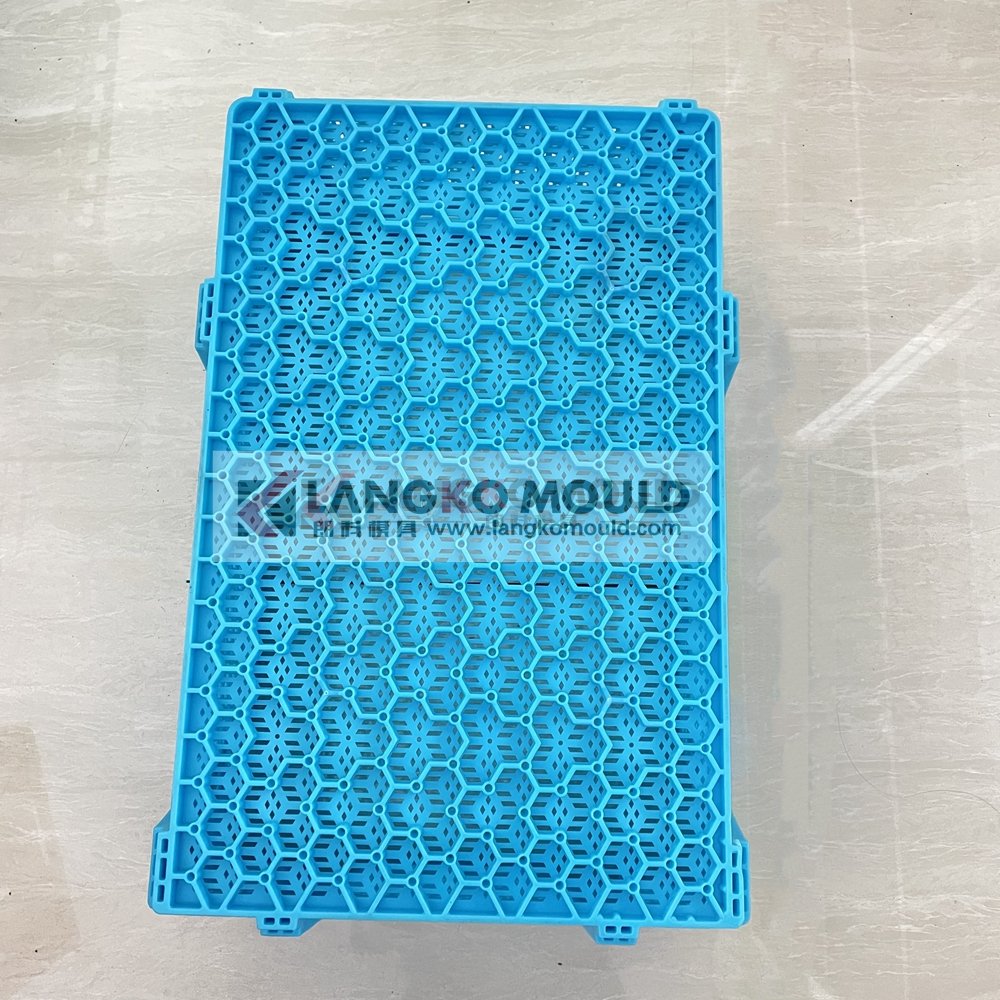

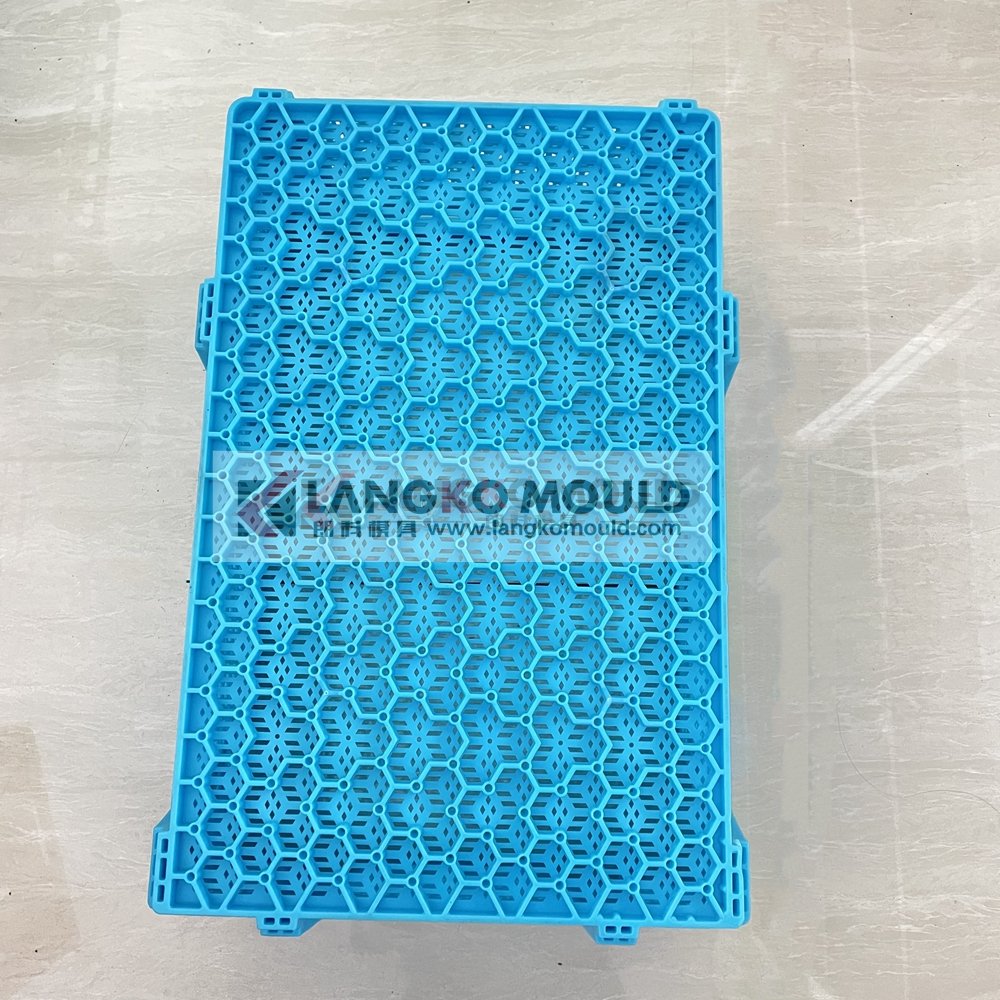

Please check with the different gate mark for the crate mold sample blow pictures:

Hot runner big gate

Hot runner valve pin gate

Cold runner

Maybe you will have curious about why cannot use three plate mold for crate mold. If you have enough budget, three plate mold also could use. But if you make crate mold, we still will recommend you to use hot runner or cold runner. It is more preferential.

Checking with the picture, you will find the crate mold cold runner only have one big gate mark on the centre of the crate, but hot runner have multi gate mark.

The below picture is Yudo hot runner system. If you use cold runner for the crate mold, the material might cooling during flow to the product. But use hot runner, there have spreader plate. The spreader plate function is to transfer the molten raw material to the injection port, and under friction and shear forces and heating, as far as possible does not change the molten material flow state.

If you have crate molds project in hand, and you not sure which injection system is better for the crate. Welcome to contact us, we will supply the good suggestion to you.

Contact person: Grace

Wechat/whatsapp:+86-18158636422

Crate, also could called logistics box.It is widely used in machinery, automobile, household appliances, light industry, electronics and other industries, can withstand acid and alkali, oil resistance, non-toxic and tasteless, can be used to store food, etc., easy to clean, easy to turn over parts, stacked neatly, easy to manage. Its reasonable design, excellent quality, suitable for the factory logistics in the transportation, distribution, storage, circulation processing.

The crate was made by injection machine. Do you know the injection system for the crate mold?

There have two injection system for the crate mold: hot runner and cold runner. But hot runner has two kinds: hot runner big gate or hot runner valve pin gate.

Please check with the different gate mark for the crate mold sample blow pictures:

Hot runner big gate

Hot runner valve pin gate

Cold runner

Maybe you will have curious about why cannot use three plate mold for crate mold. If you have enough budget, three plate mold also could use. But if you make crate mold, we still will recommend you to use hot runner or cold runner. It is more preferential.

Checking with the picture, you will find the crate mold cold runner only have one big gate mark on the centre of the crate, but hot runner have multi gate mark.

The below picture is Yudo hot runner system. If you use cold runner for the crate mold, the material might cooling during flow to the product. But use hot runner, there have spreader plate. The spreader plate function is to transfer the molten raw material to the injection port, and under friction and shear forces and heating, as far as possible does not change the molten material flow state.

If you have crate molds project in hand, and you not sure which injection system is better for the crate. Welcome to contact us, we will supply the good suggestion to you.

Contact person: Grace

Wechat/whatsapp:+86-18158636422

86-0576-81122860

86-0576-81122860