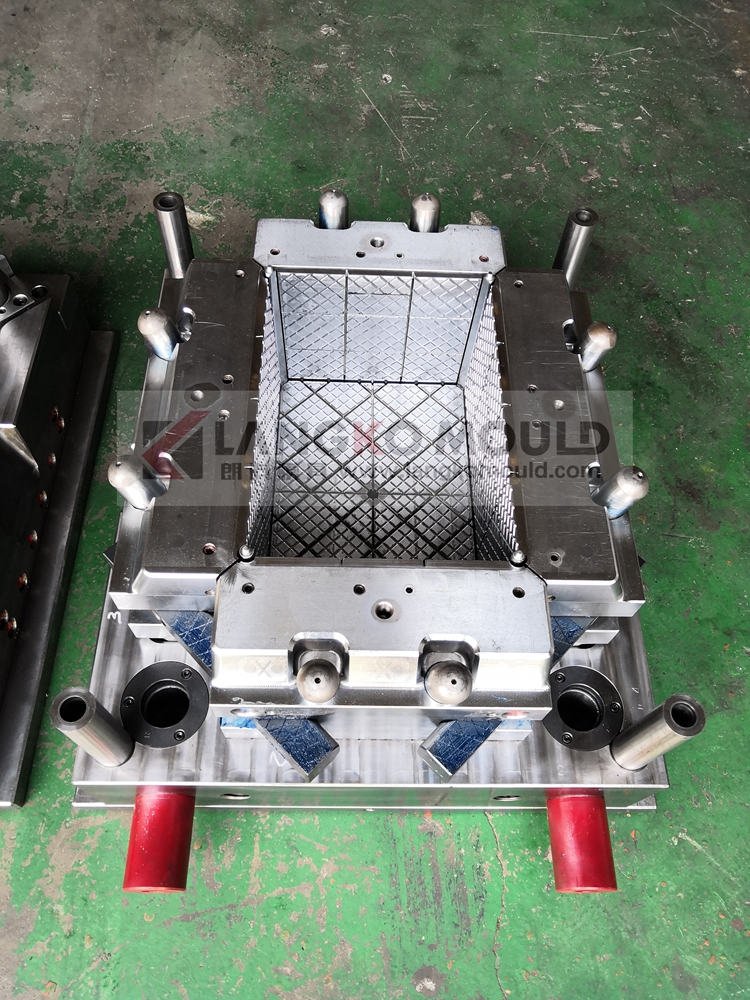

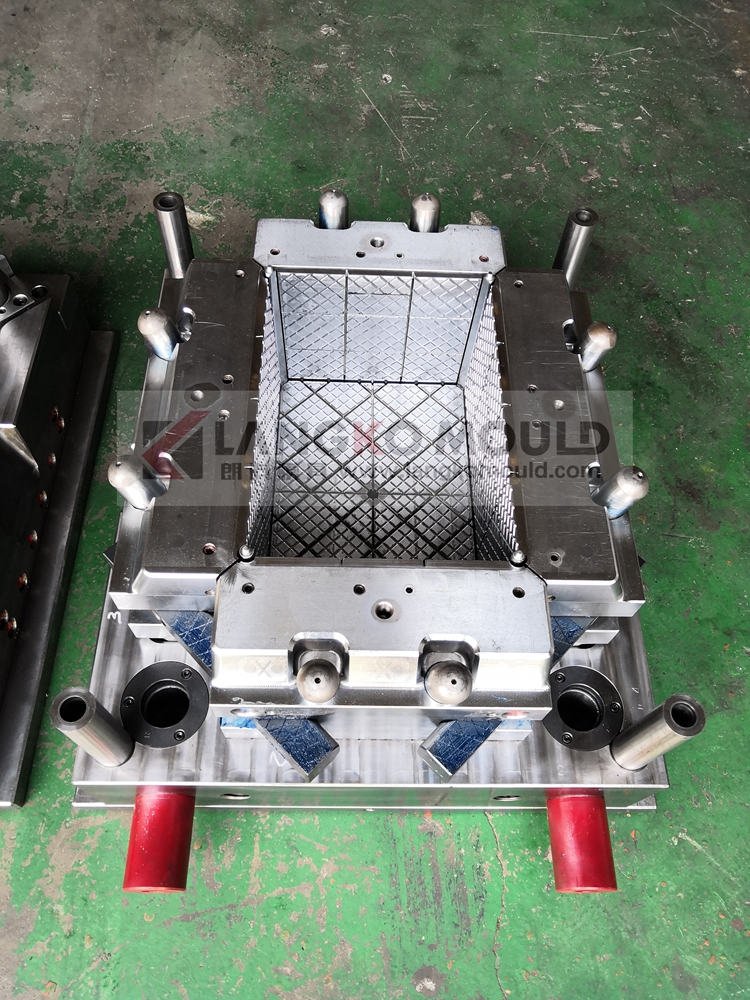

Plastic injection thin-wall crate mold

栏目:MOULD BLOG 发布时间:2025-03-12

In the production field of plastic products, injection mold technology continues to develop, among which injection thin-wall crate mold with its unique advantages and innovative technology, gradually become the focus of the industry. Today, we will delve into the characteristics, technical points and application prospects of this mold.

First, the characteristics of injection thin-wall crate mold

1. Thinner weight: normal crate thickness will be 2.6mm or more, but this crate thickness could be 2mm or less.By using thin wall design, the weight of the crate is greatly reduced on the premise of ensuring the strength and rigidity of the crate. This not only reduces the cost of raw materials, but also makes the crate more convenient in the handling and transportation process, and improves the logistics efficiency.

2.high production efficiency: normally the thin-wall crate mold will run in high speed injection machine, it could make the cycle time shorter. Compared with the traditional crate mold, the production efficiency of the thin-wall mold can be increased by more than 30%, which effectively improves the production capacity and market competitiveness of the enterprise.

3. Surface better :Due to the thin-wall thickness of the thin-wall crate, the flow resistance of the plastic melt in the mold cavity is small, and the mold cavity can be better filled, so as to obtain the product with smooth surface and high dimensional accuracy. This is very attractive for some industries with high appearance requirements, such as electronics, food, etc

Second, the technical points of injection thin-wall crate mold

1. Mold steel choose: in order meet thin-wall crate rapid prototyping requirements, mold steel need to have good thermal conductivity and wear resistance. Could use H13/S136 steel. To reduce the cycle time, the cavity or core could use some BECU.

2. Mold structure: The flow characteristics and cooling effect of plastic melt should be considered in the structural design of thin-wall crate mold. Reasonable gate location and size design can ensure that the plastic melt fills the cavity evenly, avoiding the defects such as short shot and trapped gas. At the same time, the optimized cooling water design can improve the cooling efficiency of the mold and ensure the quality and dimensional stability of the product.

3. Control of injection thin-wall crate molding process parameters: When injection molding thin-wall crate, it is necessary to accurately control injection molding process parameters, such as injection molding pressure, injection molding speed, mold temperature, melt temperature, etc. Excessive injection pressure and speed may lead to flash, deformation and other defects of the product; The improper control of mold temperature and melt temperature will affect the crystallinity and performance of the product. Therefore, it is necessary to determine the best injection molding process parameters through experiment and simulation analysis.

Third, the application prospect of thin-wall crate mold for injection molding

With the rapid development of logistics industry and the continuous improvement of environmental awareness, injection molded thin-wall crate as a reusable logistics packaging container has broad market prospects. In electronics, food, medicine, automotive and other industries, thin-walled crates are widely used in product storage, transportation and turnover. At the same time, with the continuous progress and improvement of injection thin-wall technology, the application range of injection thin-wall crate mold will continue to expand.

Moreover, the thin-wall crate mold for injection molding has an important position and broad application prospect in the field of plastic products production due to its advantages of lightweight, high efficiency and high quality. For mold manufacturing enterprises and plastic products manufacturing enterprises, continuous attention and research on injection molding thin-wall technology, improve the level of mold design and manufacturing, will help occupy a place in the fierce market competition. I hope the above content will be helpful to you to understand the injection thin-wall crate mold.

If you have any question or inquiry for the thin-wall crate mold, pls feel free to talk with us.

Wechat/whatsapp:+86-18158636422

email: sales2@langkomould.com

First, the characteristics of injection thin-wall crate mold

1. Thinner weight: normal crate thickness will be 2.6mm or more, but this crate thickness could be 2mm or less.By using thin wall design, the weight of the crate is greatly reduced on the premise of ensuring the strength and rigidity of the crate. This not only reduces the cost of raw materials, but also makes the crate more convenient in the handling and transportation process, and improves the logistics efficiency.

2.high production efficiency: normally the thin-wall crate mold will run in high speed injection machine, it could make the cycle time shorter. Compared with the traditional crate mold, the production efficiency of the thin-wall mold can be increased by more than 30%, which effectively improves the production capacity and market competitiveness of the enterprise.

3. Surface better :Due to the thin-wall thickness of the thin-wall crate, the flow resistance of the plastic melt in the mold cavity is small, and the mold cavity can be better filled, so as to obtain the product with smooth surface and high dimensional accuracy. This is very attractive for some industries with high appearance requirements, such as electronics, food, etc

Second, the technical points of injection thin-wall crate mold

1. Mold steel choose: in order meet thin-wall crate rapid prototyping requirements, mold steel need to have good thermal conductivity and wear resistance. Could use H13/S136 steel. To reduce the cycle time, the cavity or core could use some BECU.

2. Mold structure: The flow characteristics and cooling effect of plastic melt should be considered in the structural design of thin-wall crate mold. Reasonable gate location and size design can ensure that the plastic melt fills the cavity evenly, avoiding the defects such as short shot and trapped gas. At the same time, the optimized cooling water design can improve the cooling efficiency of the mold and ensure the quality and dimensional stability of the product.

3. Control of injection thin-wall crate molding process parameters: When injection molding thin-wall crate, it is necessary to accurately control injection molding process parameters, such as injection molding pressure, injection molding speed, mold temperature, melt temperature, etc. Excessive injection pressure and speed may lead to flash, deformation and other defects of the product; The improper control of mold temperature and melt temperature will affect the crystallinity and performance of the product. Therefore, it is necessary to determine the best injection molding process parameters through experiment and simulation analysis.

Third, the application prospect of thin-wall crate mold for injection molding

With the rapid development of logistics industry and the continuous improvement of environmental awareness, injection molded thin-wall crate as a reusable logistics packaging container has broad market prospects. In electronics, food, medicine, automotive and other industries, thin-walled crates are widely used in product storage, transportation and turnover. At the same time, with the continuous progress and improvement of injection thin-wall technology, the application range of injection thin-wall crate mold will continue to expand.

Moreover, the thin-wall crate mold for injection molding has an important position and broad application prospect in the field of plastic products production due to its advantages of lightweight, high efficiency and high quality. For mold manufacturing enterprises and plastic products manufacturing enterprises, continuous attention and research on injection molding thin-wall technology, improve the level of mold design and manufacturing, will help occupy a place in the fierce market competition. I hope the above content will be helpful to you to understand the injection thin-wall crate mold.

If you have any question or inquiry for the thin-wall crate mold, pls feel free to talk with us.

Wechat/whatsapp:+86-18158636422

email: sales2@langkomould.com

Next:Nothing

86-0576-81122860

86-0576-81122860