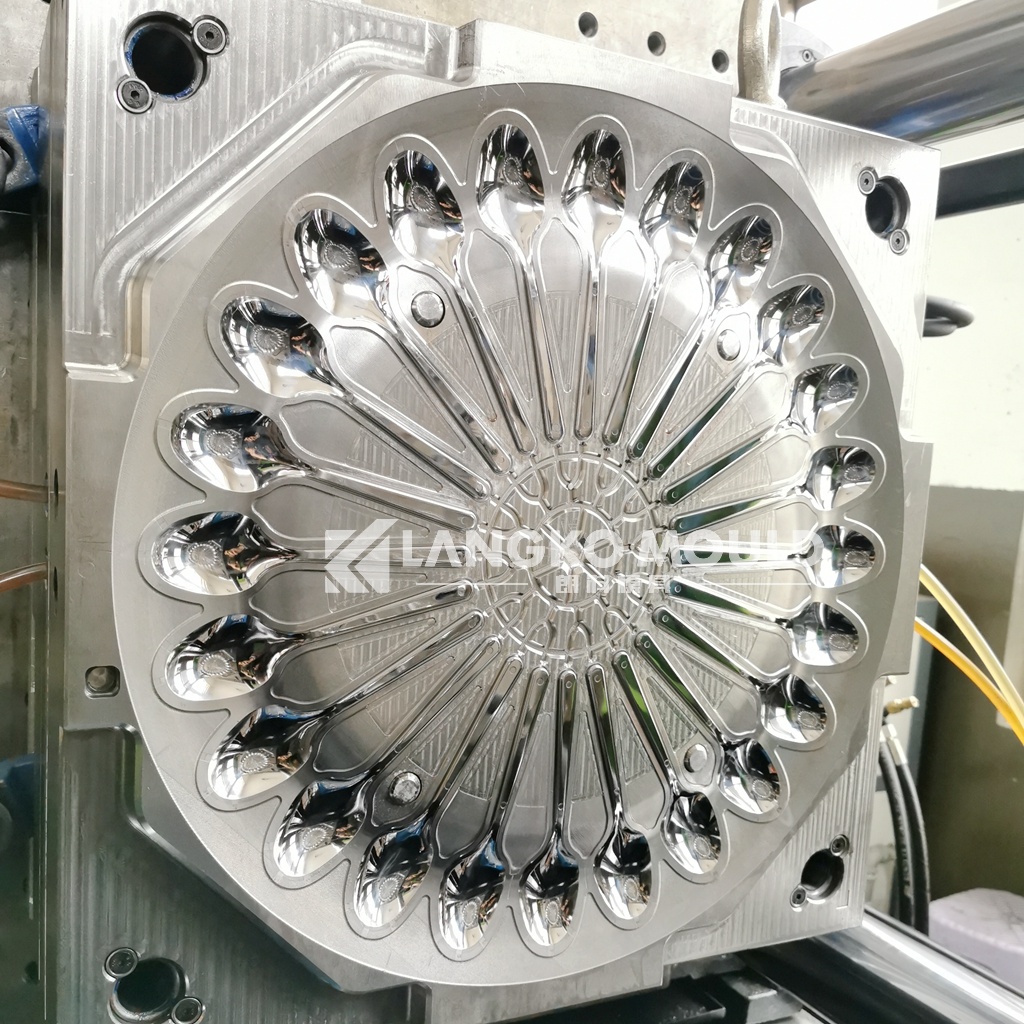

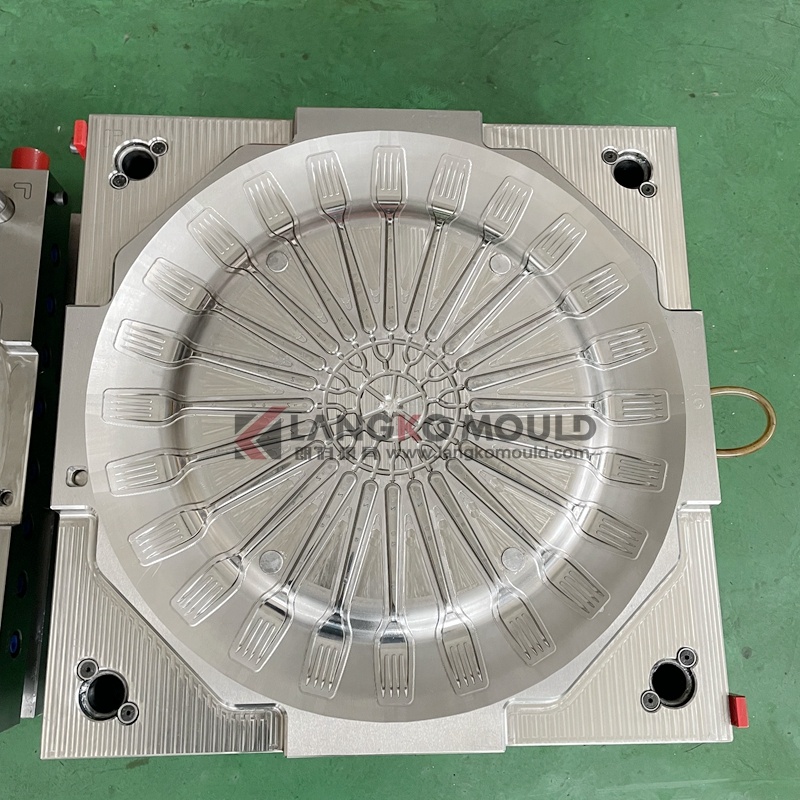

High quality knife mould, fork mould and spoon mould

栏目:MOULD BLOG 发布时间:2024-05-30

High quality knife mould, fork mould and spoon mould

Langko mould has made various types of knife mould, fork mould and spoon mould for many countries all over the world.

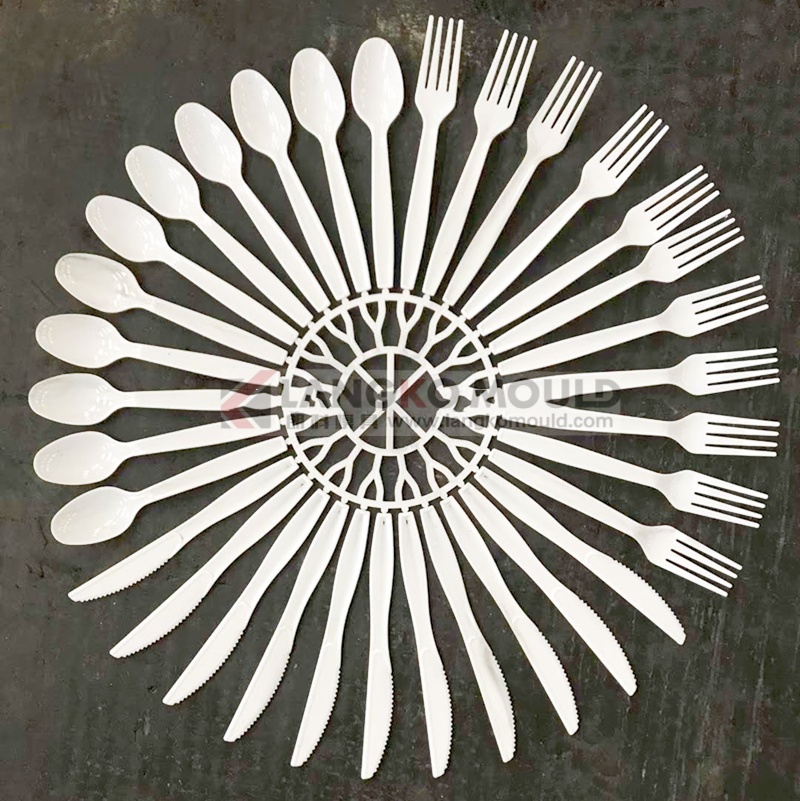

According to different usage scenario, knife mould, fork mould and spoon mould can be categorized into three types:

1. Aviation knife mould, fork mould and spoon mould

2. household knife mould, fork mould and spoon mould

3. Military knife mould, fork mould and spoon mould.

According to different shapes, knife mould, fork mould and spoon mould can be categorized in to two types:

1. Ordinary knife mould, fork mould and spoon mould

2. Foldable knife mould, fork mould and spoon mould

Different occasions, different products equipped with different knives forks and spoons, for example, restaurants use plastic knife, fork and spoon are ordinary, but food is generally equipped with foldable knife, fork and spoon. Foldable knife, fork and spoon don't take up space, easy to pack and more convenient.

The plastic material of knife, fork and spoon is generally PP or PS. We will select different mould steel according to different plastic material. Generally, for knife mould, fork mould and spoon mould, we will use H13, S136(HRC48-52)... or other quenched steel. The knife, fork and spoon belong to fast consumer goods, so knife mould, fork mould and spoon mould are generally made with multi-cavity, like 32-cavities, 36-cavities, 48-cavities... And the knife mould, fork mould and spoon mould are operated in a high speed on the plastic injection mould. So it requires high quality steel and high quality mould. Otherwise the mould life maybe short. Normally, Shape of knife mould, fork mould and spoon mould are designed as a square or round. And the gate is normally point gate. There won't be an obvious gate mark on the product. So it will be more beautiful by using this gate. About the injection system, we will use full hot runner or half hot runner. If the knife mould, fork mould or spoon mould is designed as square, then half hot runner will be more suitable, and the mould is made into insert type. The processing technology of Langko mould knife mould, fork mould and spoon mould include high-speed engraving, high-speed milling and so on. Ordinary knife mould, fork mould and spoon mould are generally two-flap moulds. The foldable knife mould, fork mould and spoon mould, based on the two-flap mould with more sliders. So foldable knife mould, fork mould and spoon mould is more difficult than ordinary foldable knife mould, fork mould and spoon mould.

Langko Mould is a professional plastic injection knife mould, fork mould and spoon mould manufacturer with 17 years experience.

Above-mentioned knife mould, fork mould and spoon mould we can customize all of them.

Above-mentioned knife mould, fork mould and spoon mould we can customize all of them.

1. Firstly, if customer has knife, fork or spoon sample, that's great. We'll scan the sample and test the point.

2. Then we'll use design software(like UG, CAD, PROE...) for 3D knife, fork or spoon product design. (It's ok if customer doesn't have sample, we'll design a knife, fork or spoon product drawing for customer based on our experience and customer's requirements.)

3. Thirdly, after 3D product design of knife, fork or spoon are confirmed, we'll start 3D knife mould, fork mould or spoon mould design. After the knife mould, fork mould or spoon mould design is finished, we will confirm with customer again, and then start the production.

Every Monday, we'll send you knife mould, fork mould or spoon mould process pictures so that customer could clearly familiar with the production status of the knife mould, fork mould or spoon mould.

4. Then we'll T1 test knife mould, fork mould or spoon mould after 40-60 days knife mould, fork mould or spoon mould design confirmed.

If you don't have time to check it in time, please don't worry, Langko Mould will provide you with knife mould, fork mould or spoon mould testing videos and knife mould, fork mould or spoon mould test reports. We will modify the knife mould, fork mould or spoon mould based on customer's feedback, then test the knife mould, fork mould or spoon mould again and send samples for customer confirmation. When we receive customer approval, we will prepare the knife mould, fork mould or spoon mould for shipment. But before shipment, Langko Mould will test chair mould again to confirm that the knife mould, fork mould or spoon mould can work properly at the customer's machine.

5. At the end, we will paint the surface of the knife mould, fork mould or spoon mould with anti-rust oil/anti-rust paint, then wrap it in bubble wrap for protection, and finally place knife mould, fork mould or spoon mould into a customized wooden case for shipment.

Langko Mould will provide you with a perfect after-service.

So, Langko Mould is your better choice. Please give Langko Mould a chance and then you will receive a high quality knife mould, fork mould or spoon mould and a caring service.

If you want to customize your own knife mould, fork mould or spoon mould, please don't hesitate to contact me!

Sale Engineer: Yulia

E-mail: sales6@langkomould.com

Wechat / WhatsApp/ Tel: +86 13375867056

Facebook: https://www.facebook.com/langkomould

Website: https://www.langkomould.com/

TAIZHOU HUANGYAN LANGKO MOULD CO.,LTD

ADD: NO.345, XINJIANG ROAD, XINQIAN STREET, HUANGYAN, 318020, TAIZHOU, ZHEJIANG, CHINA

86-0576-81122860

86-0576-81122860