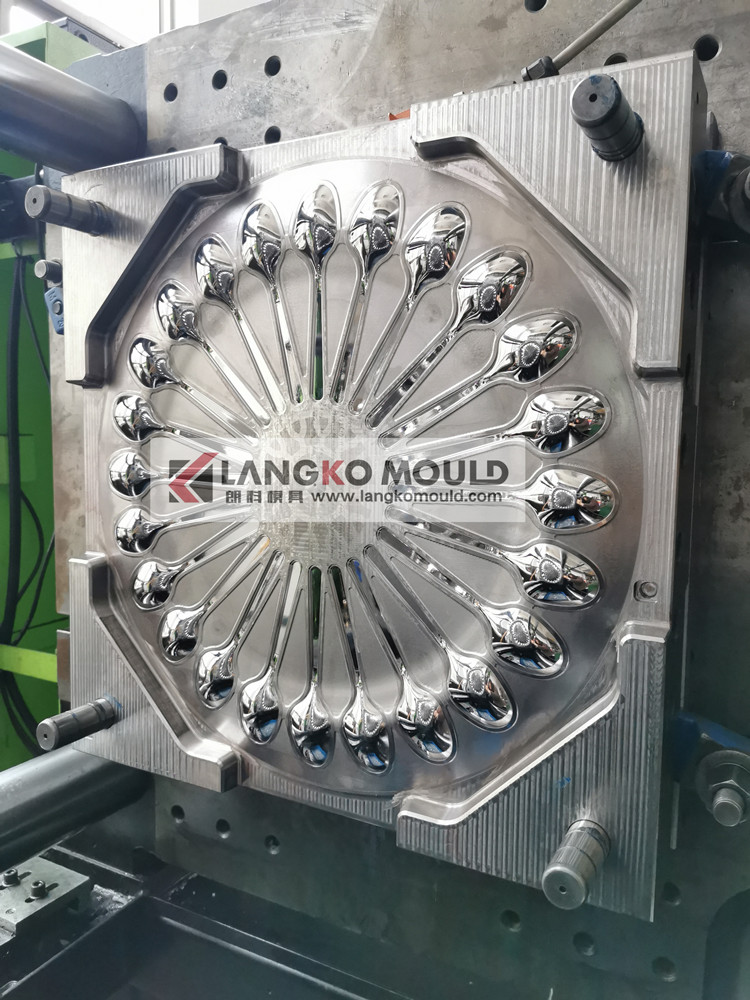

Huangyan professional plastic injection cutlery molds supplier

栏目:MOULD BLOG 发布时间:2025-07-07

In summer, disposable part have good markets, and now the demands are keep on increasing. Plastic injection cutlery molds as a important role for the disposable. Today , let we know more about the plastic injection cutlery molds.

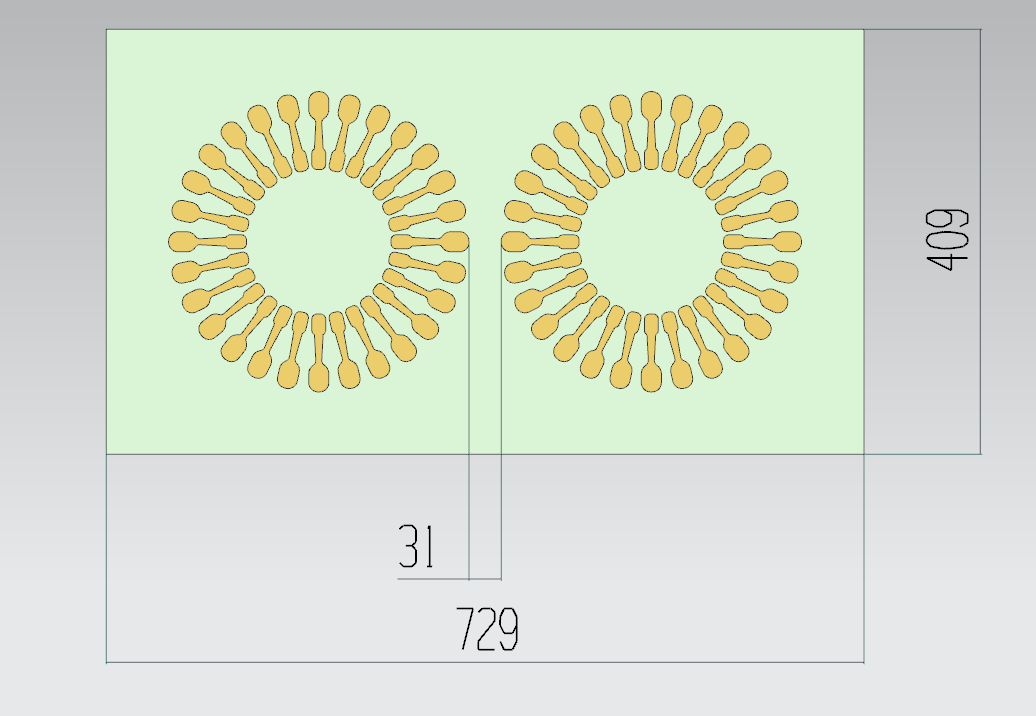

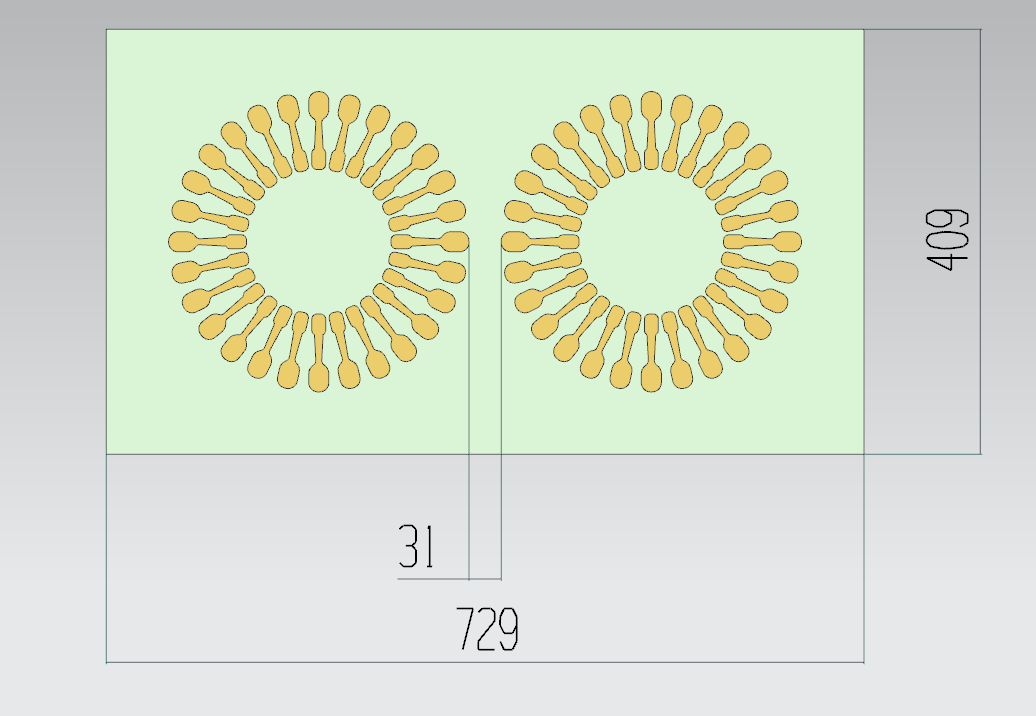

Plastic injection cutlery molds is a fast way to have the part. Due to this mold could make in different types: like family format, hamburger format, simple format.

The advantage of injection cutlery molds:

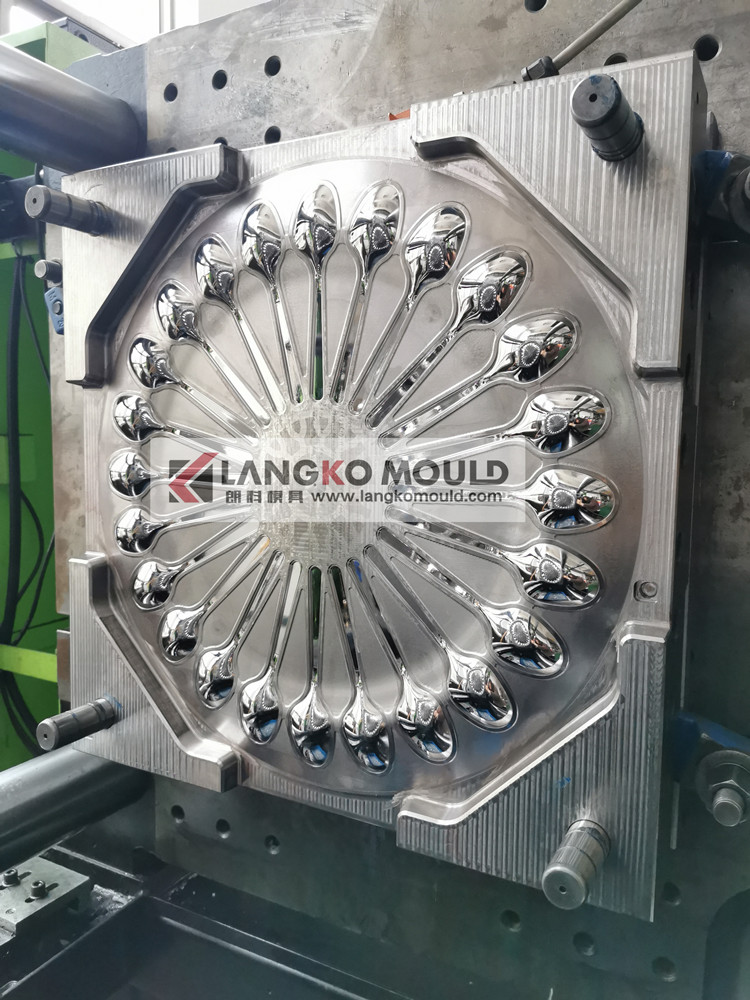

1. Efficient production: Injection molds can achieve high-speed and large-scale production. We could make 1-256-cavity mold. A mold can produce a large number of cutlery in a short time, meeting the huge market demand for disposable tableware. Some advanced injection molding machines, in combination with efficient molds, can produce dozens of cutlery per minute.

2. Precision forming: The manufacturing accuracy of the plastic injection cutlery molds is extremely high, which can ensure that the produced cutlery have precise dimensions and consistent shapes. Whether it is the thickness of the knife and fork, the depth of the spoon, or the overall appearance design, all can be produced strictly in accordance with the design requirements to ensure the stable and reliable quality of the products.

3. Diversified design: According to the different needs of customers, plastic injection cutlery molds can be designed in various shapes and size. Whether it is a simple and conventional style or a creative design with unique patterns or shapes, they can all be easily achieved through molds, meeting the aesthetic needs of different consumers.

4.Strong material adaptability: It can be produced using a variety of plastic materials, including traditional plastics and new degradable materials. With the enhancement of environmental awareness, the market demand for degradable plastic knives, forks and spoons is increasing day by day. Injection molds can well adapt to this trend and produce environmentally friendly tableware using degradable materials such as polylactic acid (PLA). And in our company, we are under making 100% biodegradable corn starch cutlery.

Due to for the different customer, the sample requirement will be different. For the plastic injection cutlery mold steel, if the thickness is less than 1mm, then recommend you to use mold base P20+ cavity and core S136/H13 steel.

If your sample thickness is thicker, then could use P20/718 steel.

Welcome to contact LANGKO MOULD if you have any order or question for the plastic injection cutlery mold.

Plastic injection cutlery molds is a fast way to have the part. Due to this mold could make in different types: like family format, hamburger format, simple format.

The advantage of injection cutlery molds:

1. Efficient production: Injection molds can achieve high-speed and large-scale production. We could make 1-256-cavity mold. A mold can produce a large number of cutlery in a short time, meeting the huge market demand for disposable tableware. Some advanced injection molding machines, in combination with efficient molds, can produce dozens of cutlery per minute.

2. Precision forming: The manufacturing accuracy of the plastic injection cutlery molds is extremely high, which can ensure that the produced cutlery have precise dimensions and consistent shapes. Whether it is the thickness of the knife and fork, the depth of the spoon, or the overall appearance design, all can be produced strictly in accordance with the design requirements to ensure the stable and reliable quality of the products.

3. Diversified design: According to the different needs of customers, plastic injection cutlery molds can be designed in various shapes and size. Whether it is a simple and conventional style or a creative design with unique patterns or shapes, they can all be easily achieved through molds, meeting the aesthetic needs of different consumers.

4.Strong material adaptability: It can be produced using a variety of plastic materials, including traditional plastics and new degradable materials. With the enhancement of environmental awareness, the market demand for degradable plastic knives, forks and spoons is increasing day by day. Injection molds can well adapt to this trend and produce environmentally friendly tableware using degradable materials such as polylactic acid (PLA). And in our company, we are under making 100% biodegradable corn starch cutlery.

Due to for the different customer, the sample requirement will be different. For the plastic injection cutlery mold steel, if the thickness is less than 1mm, then recommend you to use mold base P20+ cavity and core S136/H13 steel.

If your sample thickness is thicker, then could use P20/718 steel.

Welcome to contact LANGKO MOULD if you have any order or question for the plastic injection cutlery mold.

Next:Nothing

86-0576-81122860

86-0576-81122860