Plastic Chair Molding: The Key to Cost-Effective, Durable Seating

plastic chair is widely use in every field, and there are many shapes and types on the market, do you know how its produce? After watching my blog, you will know answer. Next I share plastic chair molding to you.

CONTACT HOTLINE

In the past, we can see many wooden chairs in home, but now plastic chair is very popular. Up to now, we have made at least 200 sets chair molds.

And are you interested in plastic chair molding?

Firstly, the raw material used in the production of plastic chairs is polyethylene or polypropylene, which is a thermoplastic polymer. It is heated and then injected into a mold, where it cools and solidifies, taking the shape of the mold.

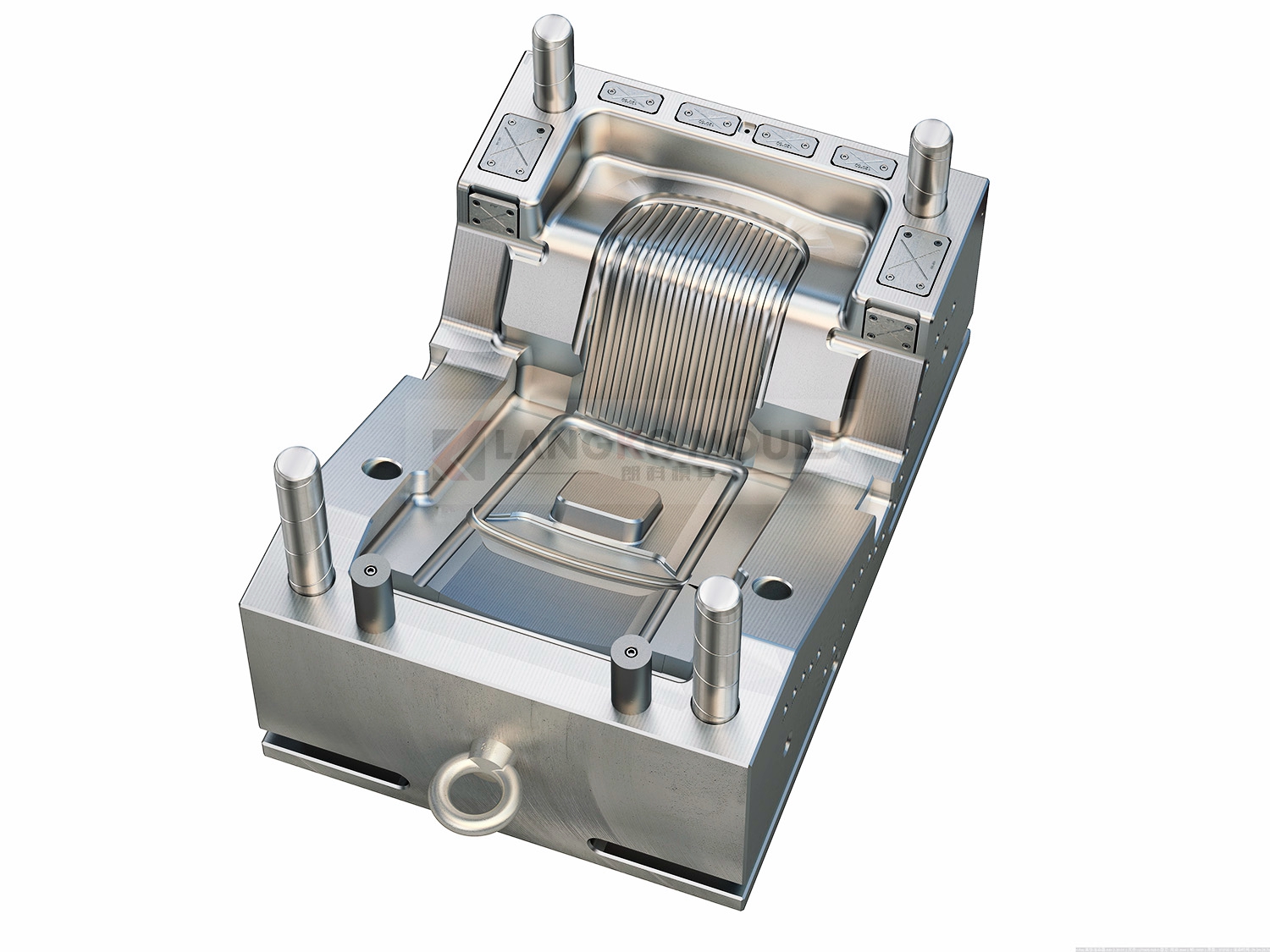

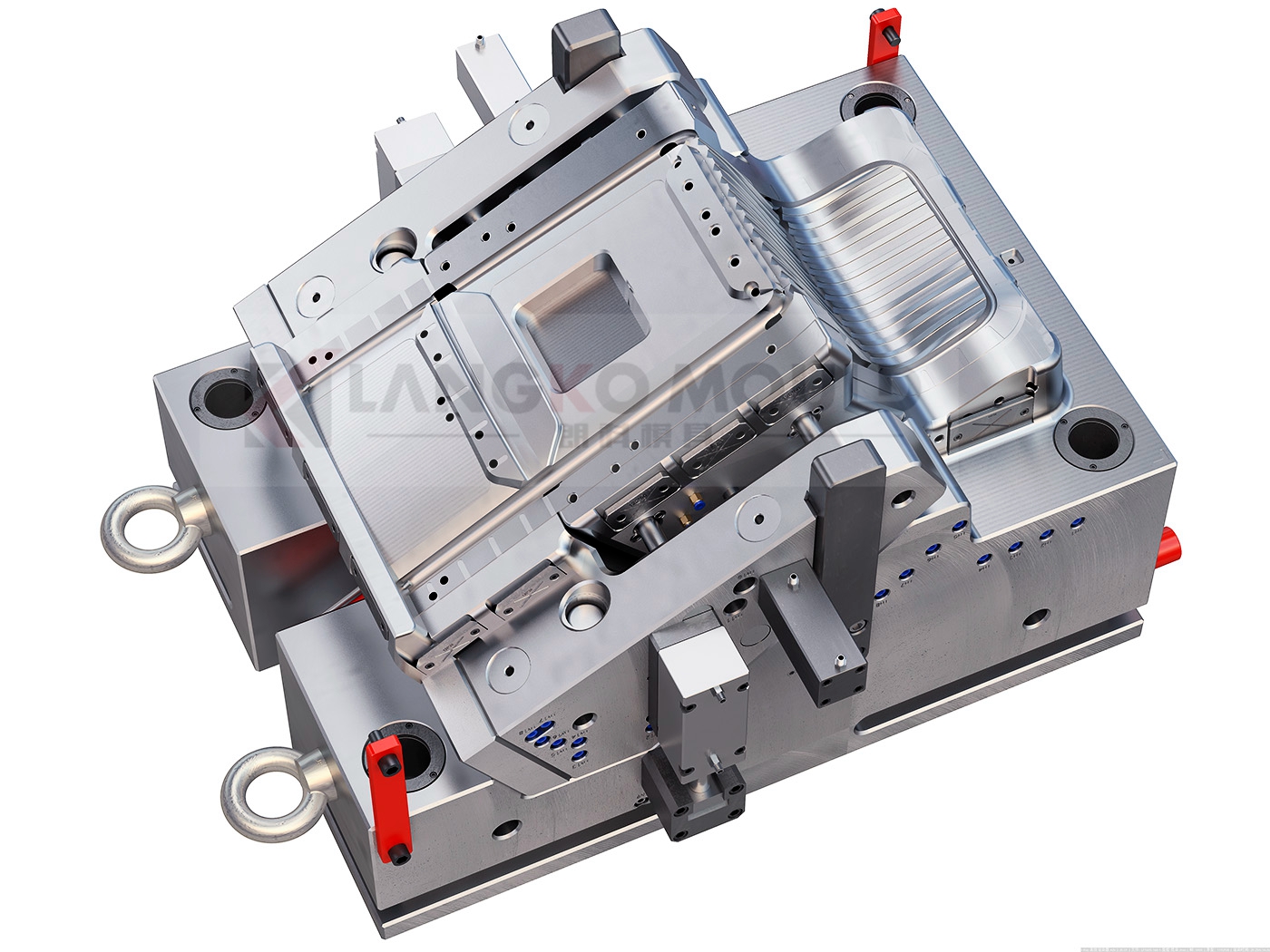

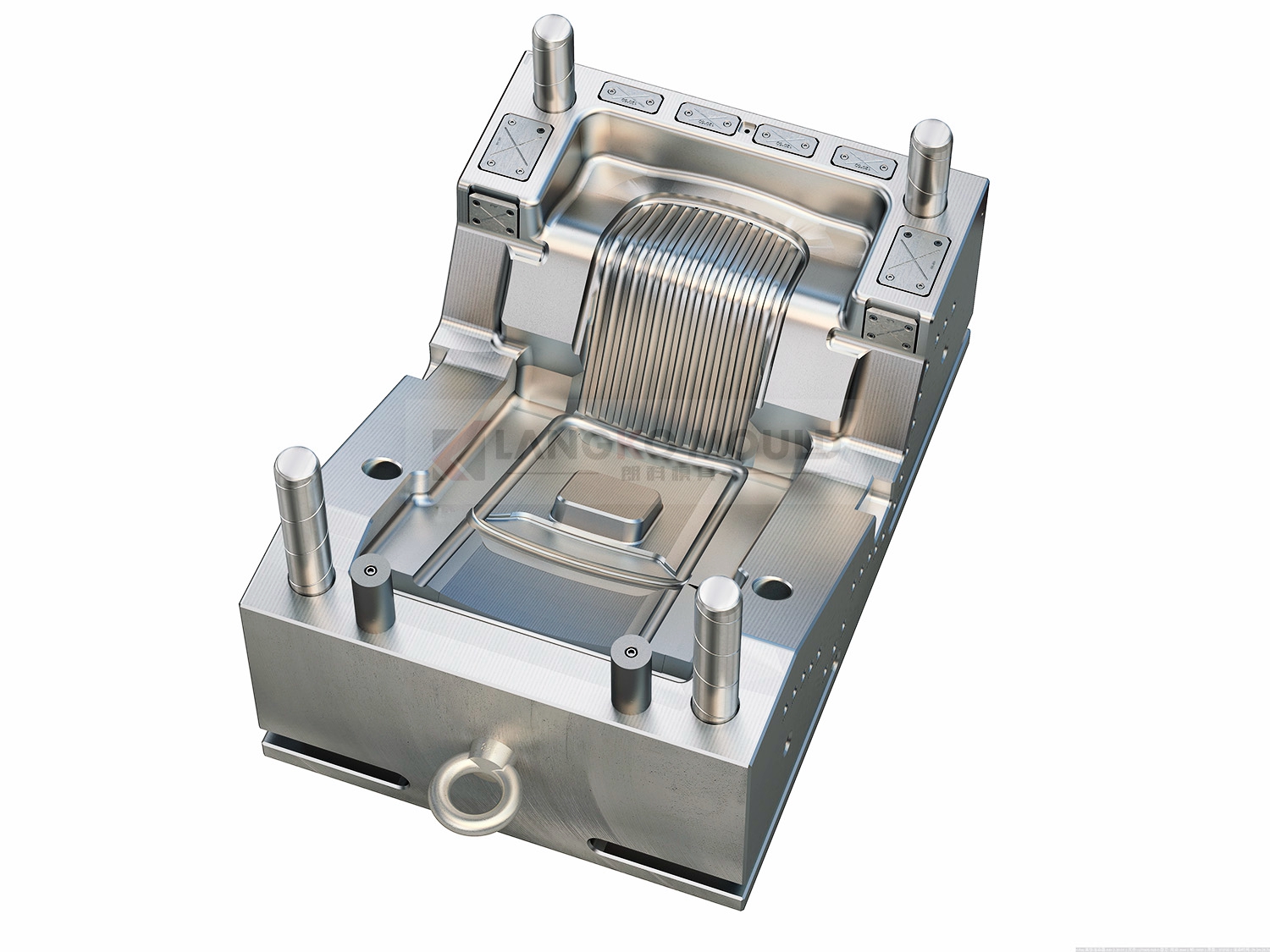

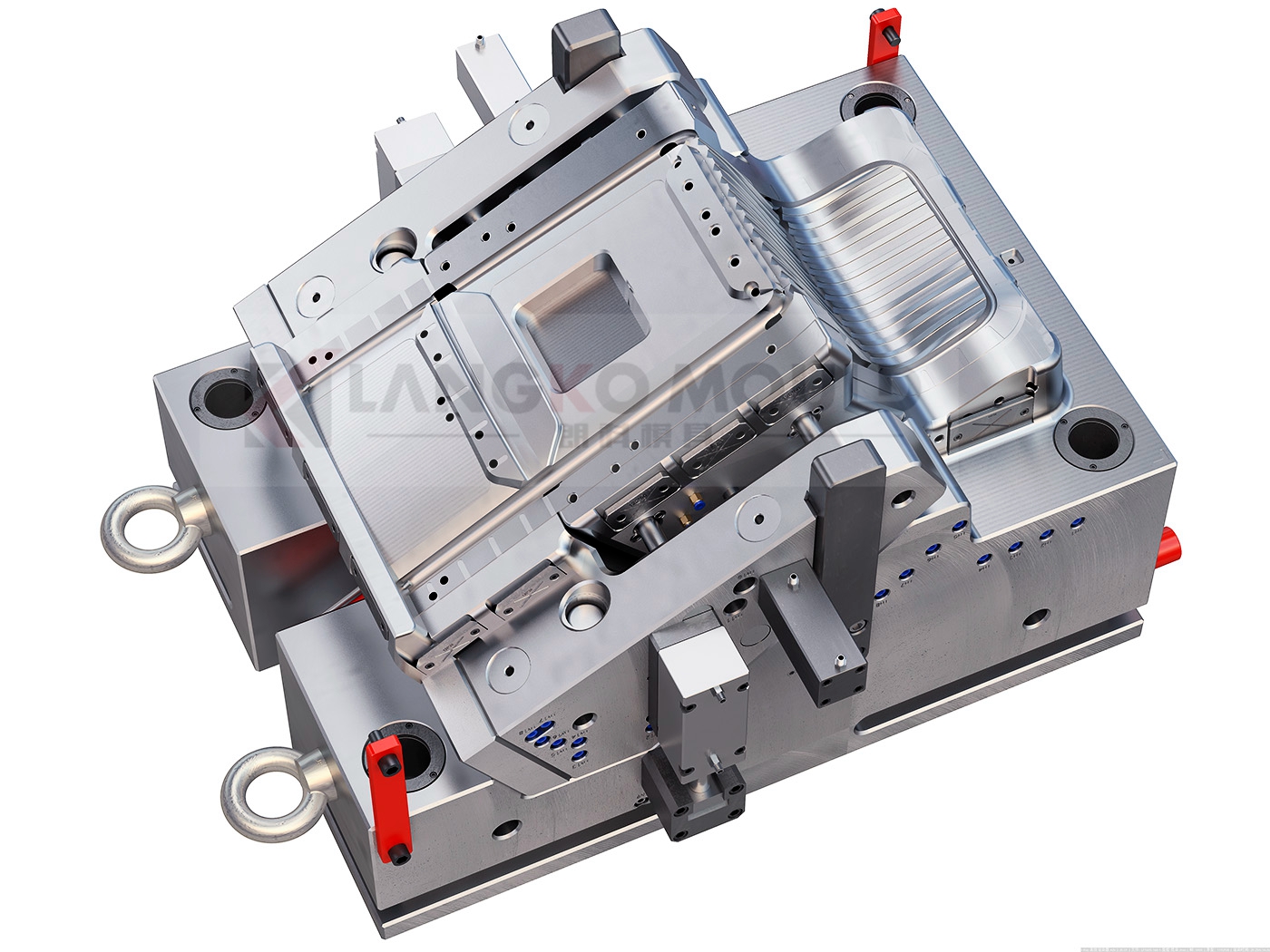

The plastic chair molding is a crucial step in the production of plastic chairs. It involves high pressure and temperature to create a precise and long-lasting product. The molds are made out of hardened steel and are precision-machined to ensure accuracy and repeatability in the production process.

After the molding process, the plastic chair is ready for use. It is lightweight, durable, and can be easily stacked or stored. The plastic chair provides a cost-effective and long-lasting solution for seating needs in both indoor and outdoor settings.

In a word, plastic chair molding is very complex and important, because we need experienced master to adjust the machine then ensure the chair can be produced smoothly. And when production finished, we will check if there is any problem on chair, untill everything is ok, then plastic chair molding process is completely over.

If you have mold projects in hand, welcome to contact us for quotations!

And are you interested in plastic chair molding?

Firstly, the raw material used in the production of plastic chairs is polyethylene or polypropylene, which is a thermoplastic polymer. It is heated and then injected into a mold, where it cools and solidifies, taking the shape of the mold.

The plastic chair molding is a crucial step in the production of plastic chairs. It involves high pressure and temperature to create a precise and long-lasting product. The molds are made out of hardened steel and are precision-machined to ensure accuracy and repeatability in the production process.

After the molding process, the plastic chair is ready for use. It is lightweight, durable, and can be easily stacked or stored. The plastic chair provides a cost-effective and long-lasting solution for seating needs in both indoor and outdoor settings.

In a word, plastic chair molding is very complex and important, because we need experienced master to adjust the machine then ensure the chair can be produced smoothly. And when production finished, we will check if there is any problem on chair, untill everything is ok, then plastic chair molding process is completely over.

If you have mold projects in hand, welcome to contact us for quotations!

Previous:Plastic chair spare mold 03

86-0576-81122860

86-0576-81122860