plastic moulding safe helmet mold taizhou supplier

栏目:MOULD BLOG 发布时间:2023-06-27

Today, we're going to discuss the importance of helmet mold and how they affect the quality of your helmet.

Electric bike riding helmet and construction helmet are very common. Many policeman often catch person who doesn't wear helmet on the road then punish them. Helmet can protect ourselves well when face dangerous.

Helmet mold is an essential part of the helmet production process, which can determine the size, shape and other important features of the helmet, providing key support for the protective performance of the helmet.

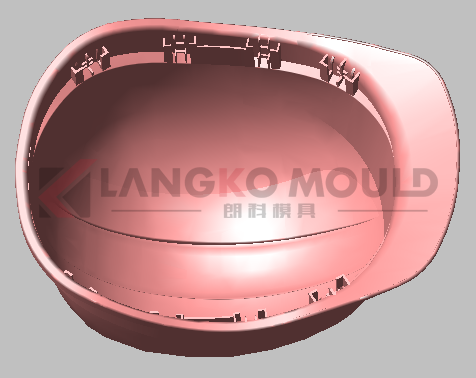

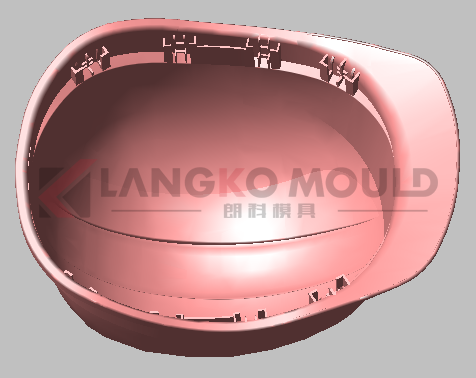

Below information is one of 20 sets helmet mold we have made. We export molds annual and get many good feedbacks.

1. Helmet information:

Mould cavity and core steel material: P20;

Cavity No.: 1-cavity;

Injection system: 1 tips hot sprue;

Ejection System: inner core-pulling + ejector pins;

Mould dimension : 500*450*500mm.

Electric bike riding helmet and construction helmet are very common. Many policeman often catch person who doesn't wear helmet on the road then punish them. Helmet can protect ourselves well when face dangerous.

Helmet mold is an essential part of the helmet production process, which can determine the size, shape and other important features of the helmet, providing key support for the protective performance of the helmet.

Below information is one of 20 sets helmet mold we have made. We export molds annual and get many good feedbacks.

1. Helmet information:

Dimension: 276.8*218.5*146.83mm;

2. Helmet mold information:Mould cavity and core steel material: P20;

Cavity No.: 1-cavity;

Injection system: 1 tips hot sprue;

Ejection System: inner core-pulling + ejector pins;

Mould dimension : 500*450*500mm.

A well-made helmet mold must have a certain hardness and strength to ensure that the helmet can provide good protection even in unexpected situations.

A good mold also needs to use high-quality materials to ensure the production quality of the helmet, as well as the comfort of the helmet itself, so that the helmet can always maintain a good appearance and function.

We have P20(HRC 28-32), 718, 718H(HRC 30-35), H13(HRC 45/48-52), S136(HRC 48-52), etc. mold steel to make helmet mold, and also you can assign yours mold steel.

A good mold also needs to use high-quality materials to ensure the production quality of the helmet, as well as the comfort of the helmet itself, so that the helmet can always maintain a good appearance and function.

We have P20(HRC 28-32), 718, 718H(HRC 30-35), H13(HRC 45/48-52), S136(HRC 48-52), etc. mold steel to make helmet mold, and also you can assign yours mold steel.

In conclusion, the helmet mold is a necessity in helmet production and provides the most important contribution to the quality of the helmet. When confirming the manufacturer of the helmet, it is recommended to select a manufacturer with high-quality molds to ensure the high quality and reliability of the helmet.

If you need more messages of helmet mold or you have mold projects on hand to quote, pls contact me.

Post by Tansy Zhang

E-mail: sales6@langkomould.com

Wechat & Whatsapp: +86-13375867056

Facebook page: https://www.facebook.com/profile.php?id=100090106601576

If you need more messages of helmet mold or you have mold projects on hand to quote, pls contact me.

Post by Tansy Zhang

E-mail: sales6@langkomould.com

Wechat & Whatsapp: +86-13375867056

Facebook page: https://www.facebook.com/profile.php?id=100090106601576

86-0576-81122860

86-0576-81122860