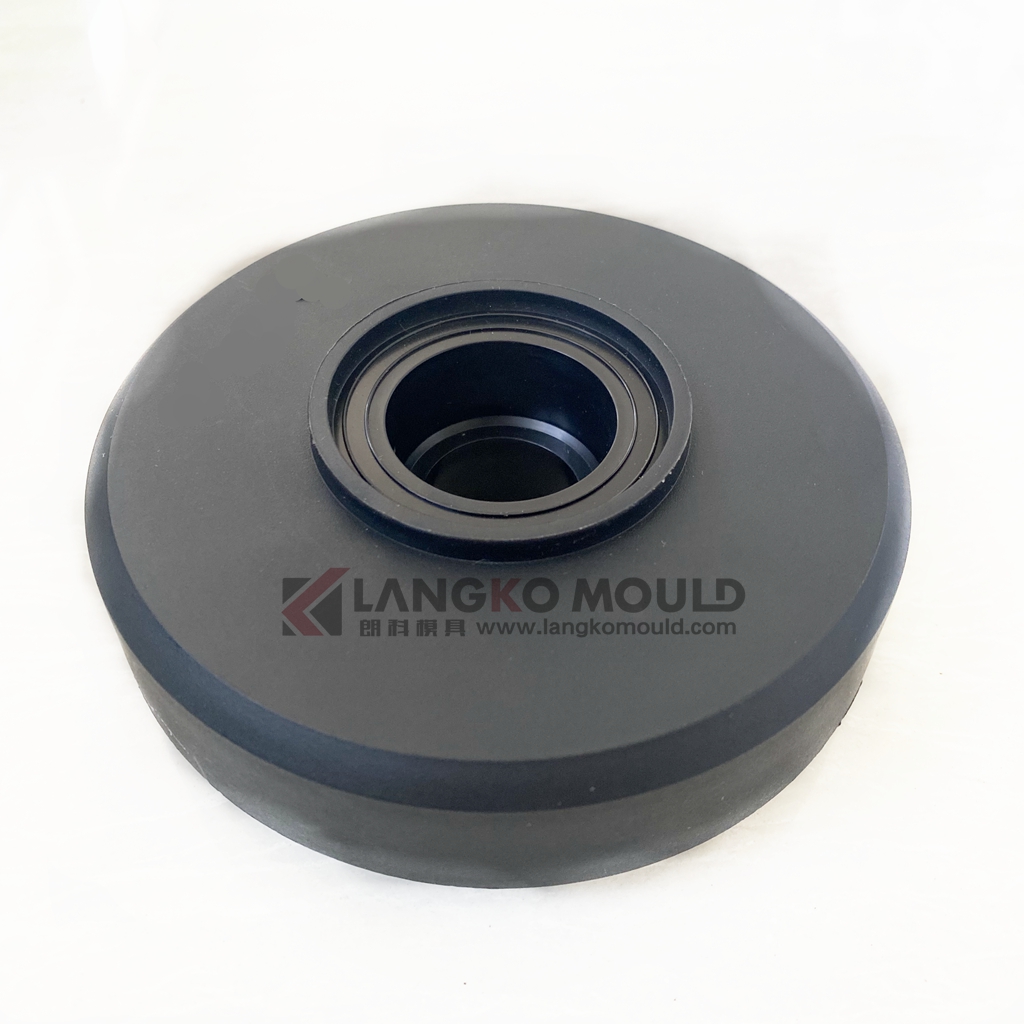

Plastic injection water purifier filter cartridge cover mold

栏目:MOULD BLOG 发布时间:2025-01-23

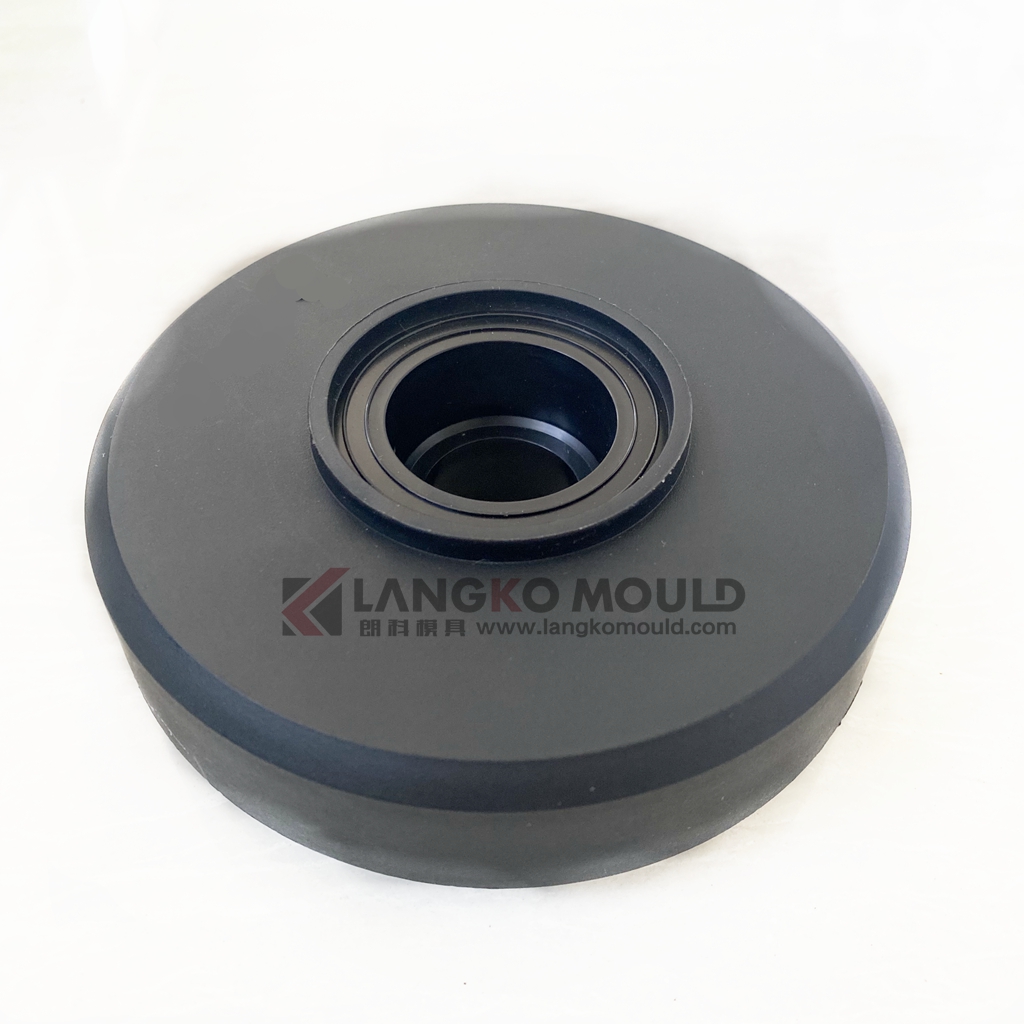

As an important part of the water purifier, the filter cartridge cover not only requires accurate size and beautiful appearance, but more importantly, it should have good sealing performance and durability. So that for the filter cartridge cover mold, the requirement is very high. Due to the size need to meet the drawing and the tolerance is very small.

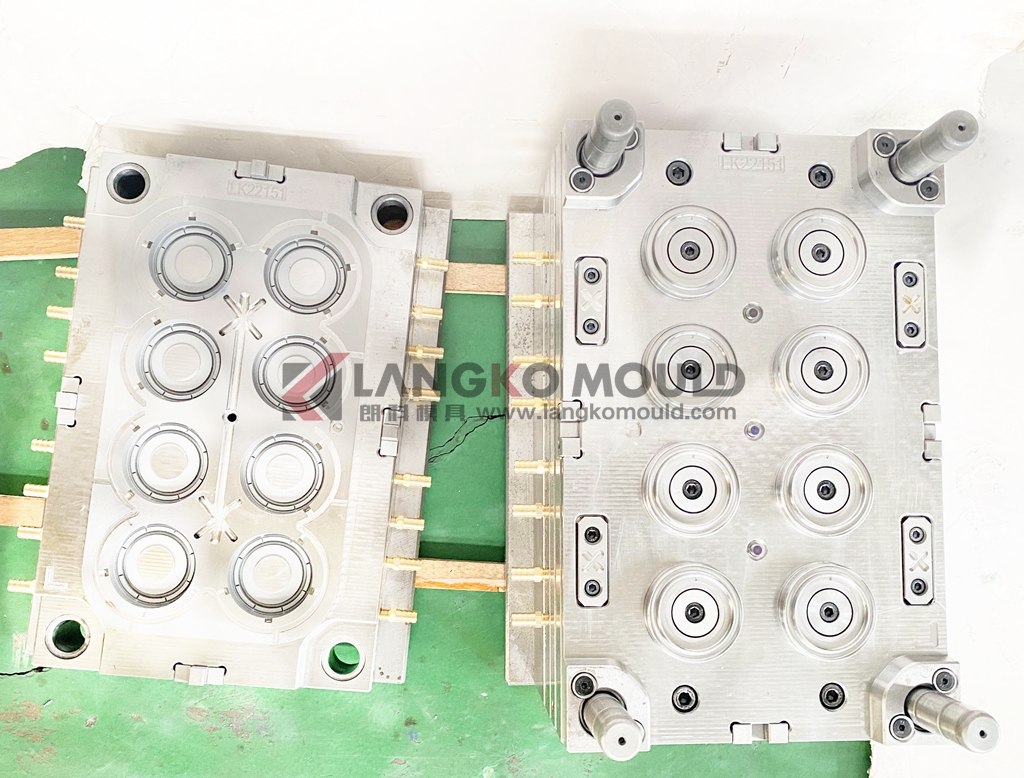

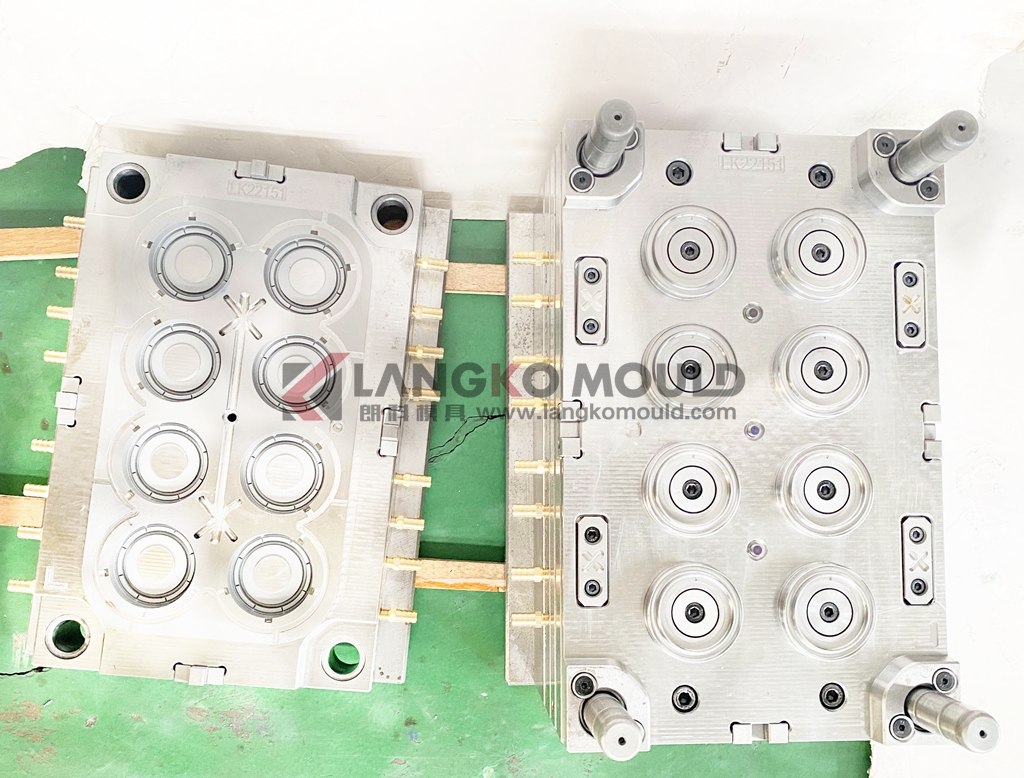

For the filter cartridge cover mold, we will make the mold design according to customer’s product drawing. After customer confirmed the mold design, we will start to tooling. All processing is very careful and precise. The cavity size, shape and surface finish of the mold need to be strictly controlled to ensure that the filter cartridge cover produced meets the design requirements.

During filter cartridge cover mold trial , the melt material will inject to the cavity, after cooling it is will become filter cartridge cover. During trial, we need to be strict on the inject temperature, pressure and speed to ensure the product quality.

The material of the filter cover of the water purifier is usually selected as plastic materials with corrosion resistance, high temperature resistance and good sealing performance, such as PP, PE, etc. These materials not only have good physical and chemical properties, but also are easy to process and form.

The production process of injection filter cartridge cover mold requires strict quality control and testing. During the production process, the filter cartridge cover mold needs to be regularly maintained and serviced to ensure its long-term stable operation. At the same time, the filter element covers produced need to be strictly inspected for quality, including size measurement, sealing performance testing, etc., to ensure that the products meet relevant standards and requirements.(trial video please click here:https://youtube.com/shorts/U5tUPGulSmg?feature=share)

In short, filter cartridge cover mold play a key role in the production of water purifier filter covers. Through precise mold design and manufacturing, strict injection molding process control and quality inspection, high-quality and high-performance water purifier filter covers can be produced, providing a strong guarantee for the normal operation of the water purifier.

For the filter cartridge cover mold, we will make the mold design according to customer’s product drawing. After customer confirmed the mold design, we will start to tooling. All processing is very careful and precise. The cavity size, shape and surface finish of the mold need to be strictly controlled to ensure that the filter cartridge cover produced meets the design requirements.

During filter cartridge cover mold trial , the melt material will inject to the cavity, after cooling it is will become filter cartridge cover. During trial, we need to be strict on the inject temperature, pressure and speed to ensure the product quality.

The material of the filter cover of the water purifier is usually selected as plastic materials with corrosion resistance, high temperature resistance and good sealing performance, such as PP, PE, etc. These materials not only have good physical and chemical properties, but also are easy to process and form.

The production process of injection filter cartridge cover mold requires strict quality control and testing. During the production process, the filter cartridge cover mold needs to be regularly maintained and serviced to ensure its long-term stable operation. At the same time, the filter element covers produced need to be strictly inspected for quality, including size measurement, sealing performance testing, etc., to ensure that the products meet relevant standards and requirements.(trial video please click here:https://youtube.com/shorts/U5tUPGulSmg?feature=share)

In short, filter cartridge cover mold play a key role in the production of water purifier filter covers. Through precise mold design and manufacturing, strict injection molding process control and quality inspection, high-quality and high-performance water purifier filter covers can be produced, providing a strong guarantee for the normal operation of the water purifier.

Next:Nothing

86-0576-81122860

86-0576-81122860