Plastic dustbin injection mold

栏目:MOULD BLOG 发布时间:2024-11-20

Plastic dustbin are necessity in daily life,regardless of the occasion.

We can divide plastic dustbin into household dustbin and industrial dustbin according to their uses.Household dustbin can be divided into three types: rotary dustbin, pedal dustbin, and simple dustbin (round, square).

Industrial dustbin are all equipped with wheels because they have large capacity and are easy to transport.

Whether it is a household dustbin or an industrial dustbin, we generally use environmentally friendly PP materials to create high-quality, beautiful and fully functional plastic dustbin.

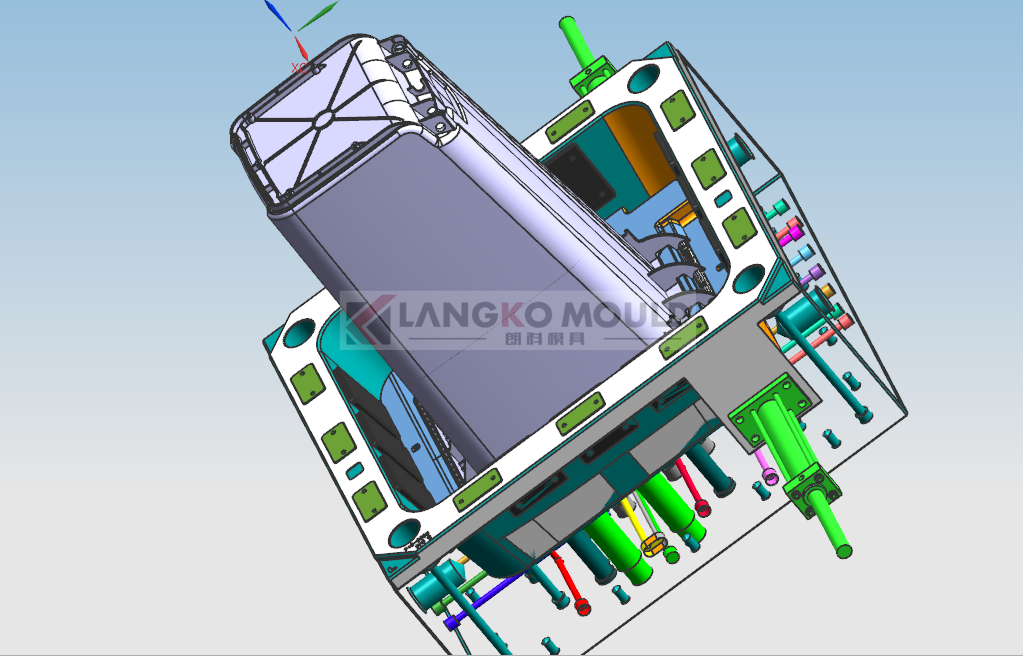

However, it is not easy to produce high-quality plastic dustbin. The premise is to make high-quality plastic dustbin molds. The production requirements of plastic dustbin molds are extremely high. From mold design, assembly to runner selection, they must be strictly checked one by one.

In addition, according to the design requirements of the product, the plastic dustbin mold design should consider increasing or decreasing the reasonable demoulding slope and do corresponding anti-deformation treatment; while ensuring quality, the reinforcement ribs can be appropriately added, which is not only convenient for demoulding, but also can save some costs; at the same time, reasonable and sufficient rounded corner design is also conducive to demoulding and increasing strength.

dustbin molds generally use hot runners with large gates and multiple gates. The gates are located on both sides of the center of the bottom of the dustbin, and the gate spacing is greater than 5 cm. The specific location is determined according to the mold flow analysis results. The advantage of this design is that the product is quickly formed and the production cycle is short. The disadvantage of multiple gates is that it is easy to cause air entrapment. According to the mold flow analysis results, find out the locations where air entrapment is easy to occur, and design ejection devices or inserts to solve the problem.

We can divide plastic dustbin into household dustbin and industrial dustbin according to their uses.Household dustbin can be divided into three types: rotary dustbin, pedal dustbin, and simple dustbin (round, square).

Industrial dustbin are all equipped with wheels because they have large capacity and are easy to transport.

However, it is not easy to produce high-quality plastic dustbin. The premise is to make high-quality plastic dustbin molds. The production requirements of plastic dustbin molds are extremely high. From mold design, assembly to runner selection, they must be strictly checked one by one.

Key points of plastic dustbin mold design

Depending on the usage scenario (home or factory), the plastic dustbin must have sufficient strength. Therefore, when designing and manufacturing the mold, it is important to ensure that the produced plastic products can be stacked under weight without bending or deformation.In addition, according to the design requirements of the product, the plastic dustbin mold design should consider increasing or decreasing the reasonable demoulding slope and do corresponding anti-deformation treatment; while ensuring quality, the reinforcement ribs can be appropriately added, which is not only convenient for demoulding, but also can save some costs; at the same time, reasonable and sufficient rounded corner design is also conducive to demoulding and increasing strength.

Plastic dustbin mold runner system

dustbin molds generally use hot runners with large gates and multiple gates. The gates are located on both sides of the center of the bottom of the dustbin, and the gate spacing is greater than 5 cm. The specific location is determined according to the mold flow analysis results. The advantage of this design is that the product is quickly formed and the production cycle is short. The disadvantage of multiple gates is that it is easy to cause air entrapment. According to the mold flow analysis results, find out the locations where air entrapment is easy to occur, and design ejection devices or inserts to solve the problem.Sliders and ejection systems of plastic dustbin molds

When demolding the plastic dustbin mold, the core is extracted by a cylinder, and then the push plate is used for ejection. According to the actual situation, a simple ejection system is designed as much as possible to reduce the probability of failure.

Sale Engineer: Luna

E-mail: market@langkomould.com

Wechat / WhatsApp/ Tel: +86 13306762335

Facebook: https://www.facebook.com/langkomould

Website: https://www.langkomould.com/

TAIZHOU HUANGYAN LANGKO MOULD CO.,LTD

ADD: NO.345, XINJIANG ROAD, XINQIAN STREET, HUANGYAN, 318020, TAIZHOU, ZHEJIANG, CHINA

86-0576-81122860

86-0576-81122860