Ingenious casting, unlocking the high-quality production code of washbasin mold

栏目:MOULD BLOG 发布时间:2025-07-16

In daily life, washbasins are indispensable household items, and their quality and practicality are closely related to the design and manufacturing process of the washbasin mold. As a professional foreign trade salesman of an injection mold factory, today we will deeply analyze the washbasin mold for everyone and explore the technology and advantages behind it.

ⅠThe core design elements of washbasin mold

1. Combination of appearance and ergonomics

The appearance of the washbasin directly affects consumers' purchasing decisions. Our mold design team keeps up with the global home design trends. Whether it is simple and modern style, retro and elegant style, or cartoon style full of childlike fun, it can be accurately presented through advanced 3D modeling technology. At the same time, taking ergonomics into full consideration, the edge curvature, depth, and handle position of the washbasin are optimized in the mold design stage to ensure comfortable grip and convenience during use.

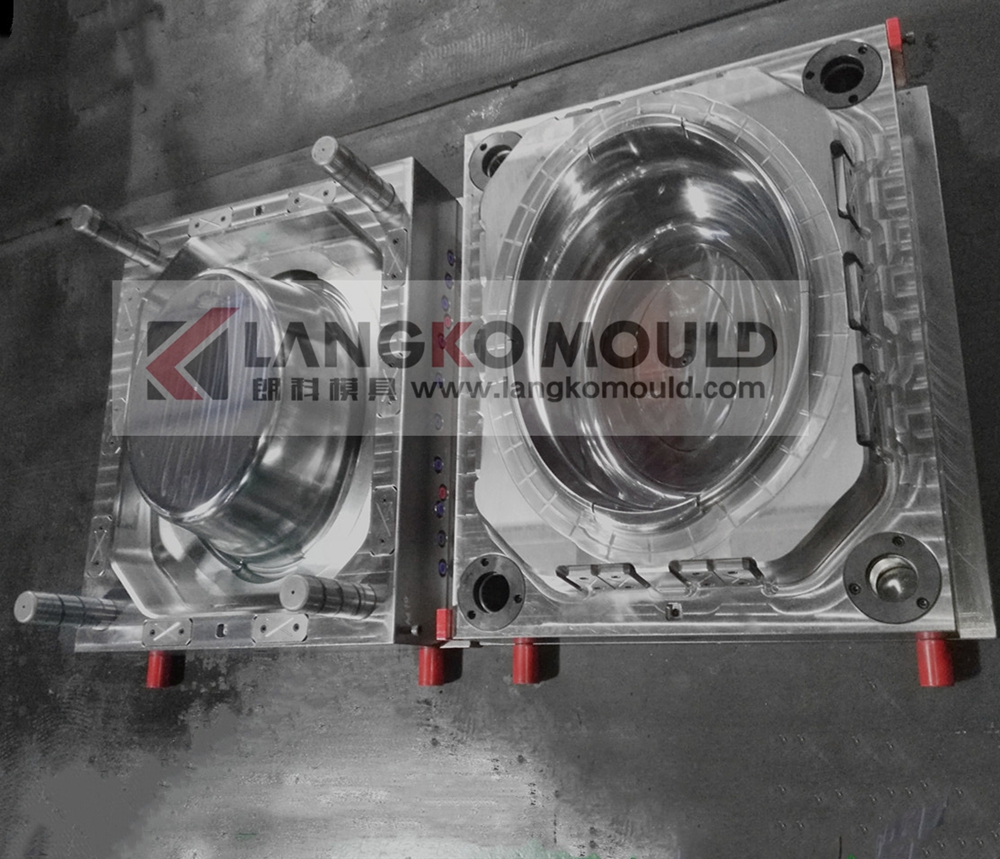

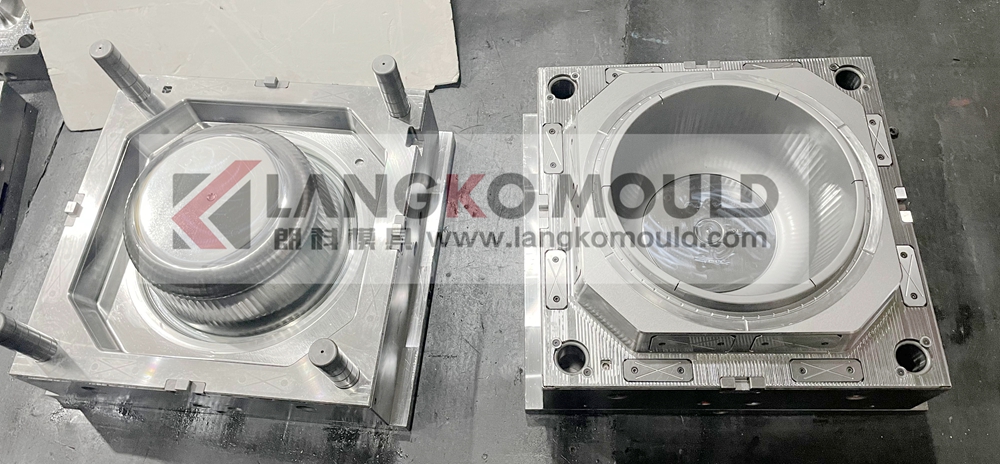

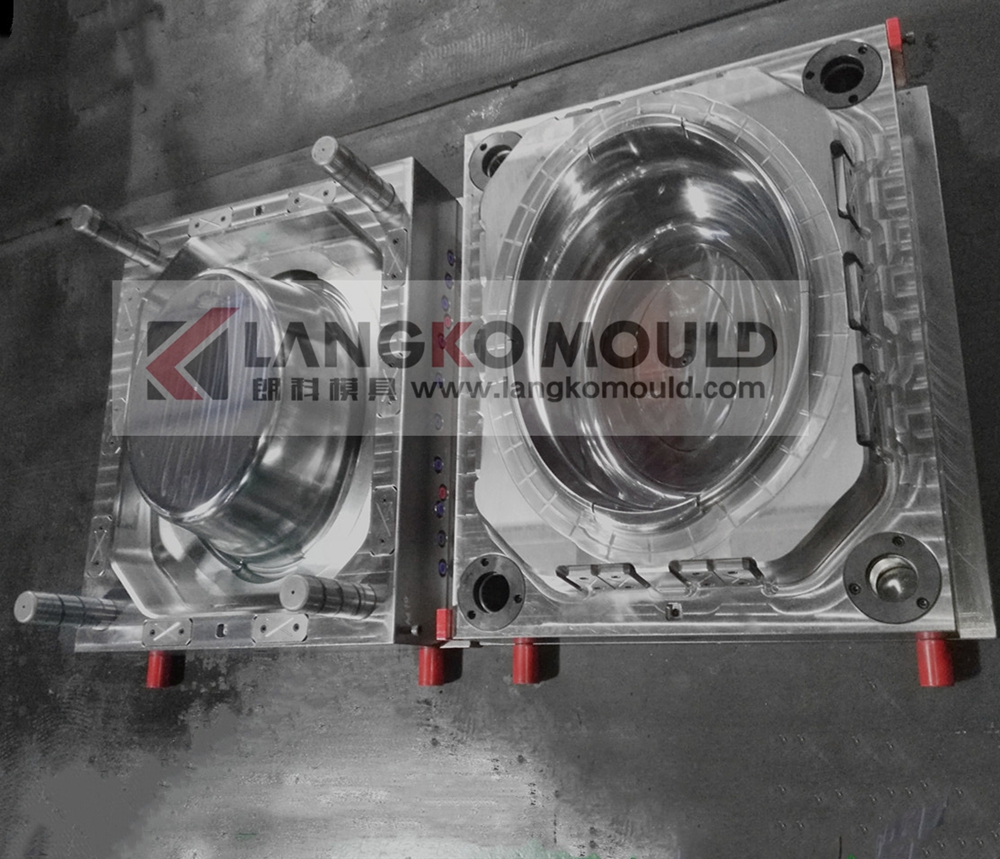

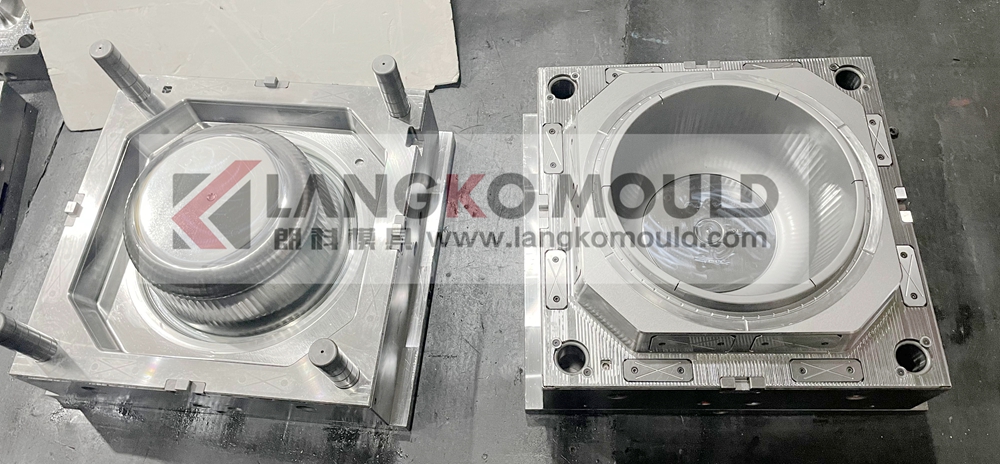

2. Control of dimensional accuracy and wall thickness uniformity

For washbasin mold, his tolerance requirements are not very high. However, we will use high-precision CNC processing equipment to control the mold size error within a very small range to ensure that the size of the produced washbasin is accurate and uniform. In addition, the mold flow analysis software can accurately calculate the flow path of the plastic melt, optimize the gate position and cooling system of the mold, ensure the uniform thickness of the washbasin wall, and avoid deformation and insufficient strength caused by local over-thickness or over-thinness.

3. Surface treatment of washbasin mold

In order to improve the texture and durability of the washbasin, the surface treatment of the mold is crucial. You can choose mirror polishing, which can make the surface of the produced washbasin smooth as a mirror and easy to clean; leather grain treatment can give the washbasin a unique texture, increase friction and prevent slipping. You can also engrave your own logo or pattern on the mold to increase the added value of the product.

Ⅱ. Injection molding process determines the quality of the washbasin

1. High-quality material adaptation

Choosing the right plastic material is the key according to different markets and usage scenarios. Most washbasins are made of PP, but they can also be produced using plastics such as PET/PC, which are relatively transparent and beautiful.

2. Accurate process parameter control

Parameters such as temperature, pressure, and injection speed during the injection molding process of the washbasin mold have a decisive influence on the quality of the washbasin. Too high a temperature will cause the plastic to decompose and discolor, while too low a temperature will lead to poor fluidity and material shortage; improper pressure will cause flash or insufficient density; too fast an injection speed will easily produce gas marks, while too slow an injection speed will affect production efficiency. With our rich experience and advanced monitoring equipment, we can accurately adjust various parameters to ensure that every produced washbasin has a good appearance and performance.

III. Competitive advantages of washbasin mold

1. Efficient production capacity

Our washbasin mold use a hot runner system, which can significantly shorten the molding cycle and improve production efficiency. At the same time, the mold structure is reasonably designed to meet the diverse order needs of customers. Even washbasin molds with complex shapes can ensure high production stability and yield.

2. Customized service

As a washbasin mold supplier, we are well aware of the differences in preferences of consumers in different countries and regions. Whether it is the pattern, functional design, or superposition requirements of the washbasin, we can provide customers with a full range of customized services. From the communication and confirmation of the mold design plan to the sample production, we maintain close communication with customers throughout the process to ensure that the final product meets market demand.

Although the washbasin is small, it contains great technology. High-quality washbasin molds are the basis for producing high-quality washbasins, and are also the key for enterprises to stand out in the market competition. If you are looking for a professional and reliable washbasin mold supplier, please feel free to contact us. We will use professional technology and high-quality services to create a satisfactory mold solution for you and work together to develop the international home furnishings market!

Contact person:Grace

ⅠThe core design elements of washbasin mold

1. Combination of appearance and ergonomics

The appearance of the washbasin directly affects consumers' purchasing decisions. Our mold design team keeps up with the global home design trends. Whether it is simple and modern style, retro and elegant style, or cartoon style full of childlike fun, it can be accurately presented through advanced 3D modeling technology. At the same time, taking ergonomics into full consideration, the edge curvature, depth, and handle position of the washbasin are optimized in the mold design stage to ensure comfortable grip and convenience during use.

2. Control of dimensional accuracy and wall thickness uniformity

For washbasin mold, his tolerance requirements are not very high. However, we will use high-precision CNC processing equipment to control the mold size error within a very small range to ensure that the size of the produced washbasin is accurate and uniform. In addition, the mold flow analysis software can accurately calculate the flow path of the plastic melt, optimize the gate position and cooling system of the mold, ensure the uniform thickness of the washbasin wall, and avoid deformation and insufficient strength caused by local over-thickness or over-thinness.

3. Surface treatment of washbasin mold

In order to improve the texture and durability of the washbasin, the surface treatment of the mold is crucial. You can choose mirror polishing, which can make the surface of the produced washbasin smooth as a mirror and easy to clean; leather grain treatment can give the washbasin a unique texture, increase friction and prevent slipping. You can also engrave your own logo or pattern on the mold to increase the added value of the product.

Ⅱ. Injection molding process determines the quality of the washbasin

1. High-quality material adaptation

Choosing the right plastic material is the key according to different markets and usage scenarios. Most washbasins are made of PP, but they can also be produced using plastics such as PET/PC, which are relatively transparent and beautiful.

2. Accurate process parameter control

Parameters such as temperature, pressure, and injection speed during the injection molding process of the washbasin mold have a decisive influence on the quality of the washbasin. Too high a temperature will cause the plastic to decompose and discolor, while too low a temperature will lead to poor fluidity and material shortage; improper pressure will cause flash or insufficient density; too fast an injection speed will easily produce gas marks, while too slow an injection speed will affect production efficiency. With our rich experience and advanced monitoring equipment, we can accurately adjust various parameters to ensure that every produced washbasin has a good appearance and performance.

III. Competitive advantages of washbasin mold

1. Efficient production capacity

Our washbasin mold use a hot runner system, which can significantly shorten the molding cycle and improve production efficiency. At the same time, the mold structure is reasonably designed to meet the diverse order needs of customers. Even washbasin molds with complex shapes can ensure high production stability and yield.

2. Customized service

As a washbasin mold supplier, we are well aware of the differences in preferences of consumers in different countries and regions. Whether it is the pattern, functional design, or superposition requirements of the washbasin, we can provide customers with a full range of customized services. From the communication and confirmation of the mold design plan to the sample production, we maintain close communication with customers throughout the process to ensure that the final product meets market demand.

Although the washbasin is small, it contains great technology. High-quality washbasin molds are the basis for producing high-quality washbasins, and are also the key for enterprises to stand out in the market competition. If you are looking for a professional and reliable washbasin mold supplier, please feel free to contact us. We will use professional technology and high-quality services to create a satisfactory mold solution for you and work together to develop the international home furnishings market!

Contact person:Grace

Next:Nothing

86-0576-81122860

86-0576-81122860